- #Machine Vision

- #Motors

- #Panel

- #Pressure & Flow

- #Process Management Solutions

- #Sensors and Safety

- #Materials handling

- #Process automation

Food and Beverage Manufacturing – Improving Flexibility

A guide for system integrators and machine builders

The food and beverage industry is the UK’s largest manufacturing sector and has many manufacturing challenges. The slightest change in the weather, for example, can impact food and beverage manufacturers, requiring changes to production.

As a machine builder or system integrator, knowing the key trends in the food and beverage market will help you to create an effective solution for your customers.

In this guide we’ll look at the key food and beverage trends in 2022. We’ll then focus on one trend in particular: improving flexibility in food and beverage manufacturing.

We’ll cover what flexible manufacturing is, its benefits to the food and beverage sector, and ways to achieve it. And we’ll suggest products that may help with increasing flexibility in your manufacturing system.

Food and beverage automation trends in 2022

Food and beverage automation integrates technology across a production line so that companies can streamline their process, saving costs and reducing the need for human labour at each stage.

Here are some of the key trends in 2022:

- Sustainable manufacturing is becoming the norm

- There’s been an increasing focus on food hygiene and safety since Covid-19

- There’s an increased need for accuracy of inspection

- Big brands are aiming to move to recyclable, reusable, or compostable packaging by 2025

- Food manufacturing automation capabilities are increasing

- Developing flexible manufacturing to be able to adapt to future changes and innovations

Trend: Improving flexibility in food and beverage manufacturing

Flexibility helps in adapting or changing processes, such as changes in production volume, mobility and quality.

What is flexible manufacturing?

Flexible manufacturing means being able to adapt to the different needs of customers and changes in production.

To be flexible, your system would be able to cope with production changes within a matter of hours and days – without having to create a whole new manufacturing process!

This is where automation comes into play. Examples of automation include food quality inspection, robotics, conveyor lines, and sealing and labelling.

What are the benefits of flexible manufacturing in food and beverage?

- Improved quality of products with less chance of product recalls

- A process that can adapt easily to change

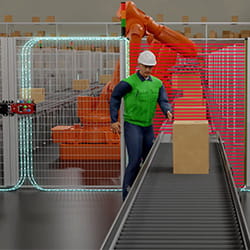

- Protection of workers’ safety

- Traceability throughout production

- Increased productivity and ROI

- Meeting customer needs

- Reduced waste and saving on costs

- Improved hygiene and sanitation

7 ways to achieve flexible manufacturing

1. Pre-wired systems

Customers prefer to have everything set up in their system and ready to go so that they can change processes easily. You can request products tailored to the customer’s needs such as specific cable lengths.

Examples of pre-wired products:

- Pre-assembled beacons with M12 connection and plugs with male and female threads, universal and easy to install

- Pre-assembled compact signal towers, with different cable lengths available on request

2. Error recognition and quality checking throughout the process

Address problems early in the process so you can meet demands for flexibility. Quality inspection can eliminate any human-related errors, and consistency can be achieved in elements like flavour, taste and texture.

Some examples of products used for error recognition and quality checking include:

- Various machine vision cameras for food inspection to test geometrics, packaging and for foreign objects, and to analyse food quality and freshness

- Smart vision sensors and cameras to check whether the quality of an object is ‘good’ or ‘not’, displayed on a computer linked to the sensor

- Smart vision sensors and cameras for quality control, identification and positioning. Their software guides the user step-by-step. This can be used, for example, to check that bottle caps are firmly secured

3. Traceability

By using automation, you can trace where production faults occurred and make appropriate alterations to prevent a product recall or low-quality product.

The following are examples of products that help to monitor and change future processes and so increase flexibility:

- Smart vision sensors to check whether an object is ‘good’ or ‘not good’

- Image-based scanners for fast omni-directional barcode scanning during the barcode stage

- SWIR cameras combined with speciality lenses can be used for food inspection to check damage within food, for example bruises within an apple

- Various industrial protocols and networks such as IIOT and Ethernet-enabled products can be more effective than recognition by the human eye

4. Use components with quick turn-around and easy maintenance

Flexibility requires quick turn-around times and quick and easy maintenance products. Examples include:

- Easily pluggable connectors

- Products with IO-Link interface

- IIoT enabled products

- Motor drives with built-in Profinet and Ethernet/IP, easily interfaced with many PLC systems

- Motors and drives that work with many protocols

5. Increase safety for workers

Flexibility can mean that people do not have to undertake complex tasks that could put them in danger. By utilising automation and all its various functions, people also do not have to undertake often repetitive critical tasks where consistency is difficult to achieve.

Examples of safety products:

- Non-contact safety switches

- Solenoid interlock switches with IP69K

- Safety relays

- Slip rings

- IP69K beacons for alerting and notification

6. Quick hygiene and sanitation processes

It is critical to get hygiene and sanitation right in food and beverage manufacturing.

The following ideas can help you maintain high hygiene levels during changes in the process, and without wasting time.

Washdown

Develop an easy washdown procedure with well-designed equipment made from stainless steel and IP-rated equipment.

IP-rated products include:

- Cable conduits and cable glands with IP68K

- IP69K push buttons

- Stainless steel motors and safety switches with IP69K

- FDA and Ecolab approved products such as cable entry systems are suitable for washdown

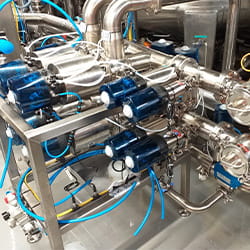

CIP cleaning

CIP systems clean, rinse and sanitize pipes to remove any excess product. A twin-screw pump, for example, enables CIP cleaning and product handling within just one pump.

Twin-screw pumps ensure:

- An additional CIP pump is not necessary, saving costs and time

- High hygiene level

- Quick product handling and CIP cleaning

OEM Automatic process instrumentation, such as pigging valves, pressure gauges and turbidity sensors are suitable for CIP cleaning.

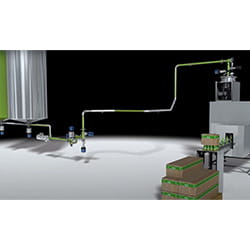

7. Reduce wastage

Flexibility means you can change production direction and switch functions without wasting too many resources. Reducing waste not only saves you resources but also improves the environmental image of your manufacturing process.

An example of a product that helps reduce waste is a pigging system. Here a pig is pushed into the pipe to stop media getting through, thus enabling the pipe to be quickly scraped and cleaned.

A pigging system ensures:

- Less waste and less use of cleaning agent

- Reduction in water consumption

- Lower energy consumption

This guide has outlined ways of developing flexibility in food and beverage manufacturing and suggested some suitable products to help you create a flexible food and beverage production line.

Please contact us if you are interested in knowing more about any of the products mentioned above.

Email [email protected] or call 0116 427 1415 to find out more.

Related Products

P Series, Beacon, Ø75mm

- Ø75mm, Modular beacon

- Steady, Flashing, Strobe and Multi-Coloured Strobe light options

- Wide control voltage range

Signal Tower Ø 30mm, Pre-assembled

- Compact (ready to use) LED signal tower

- Tower is built and supplied according to customer‘s requirements

- Wide control voltage range

KES-GB-FDA IP66 FDA Approved Cable Entry with strain relief

KES-GB-FDA

- For cable, pipe & hose diameters 3.2mm to 20.5mm

- Double Sealing to IP66

- FDA approved material, Ecolab approved - Hygienic design for wash down

- Polymide 6.6 Glass fibre reinforced core

- Integrated strain relief to EN62444

Signal Tower Ø 70mm, Pre-assembled

- Compact (ready to use) LED signal tower

- Tower is built and supplied according to customer‘s requirements

- Wide control voltage range

LIQUID-TIGHT-FOOD - Protective Metal Conduit

- Food safe PU seathing

- Special fibre sealing

- Liquid tight

- Cold strip galvanised steel / PU

US-FOOD metal connector

- For Flexa FOOD -series conduits

- Stainless steel

- IP68 rated

Ultra Flat

Progress® ultraFLAT

- Flush fitting

- Ideal for restricted space

- Externally tamperproof

- -40°C…+100°C

- IP68 up to 10 bar, IP69

Ultra Flat Stainless Steel

Progress® ultraFLAT A2, Progress® ultraFLAT A2 HT

- Flush fitting

- A2 - AISI 303

- FKM seals (FDA approved) or FPM seals

- EHEDG certified for the food industry

- IP68 up to 10 bar, IP69

Flush Non-Illuminated Pushbutton

Flush Head

- IP66 / IP69K

- Spring return or latching

- Optional text or symbol

Flush Illuminated Pushbutton

Flush Head

- IP66 / IP69K

- Spring return or latching

- Optional text or symbol

- Illuminate with LED blocks

One Piece Pilot Lights

Complete Pilot Light With Integrated LED

- IP66 / IP69K

- 12-24V, 115V, 230V ac/dc

- Compact 37.2 mm behind panel depth

- Long lifetime up to 100,000 hours

Control boxes, complete

Crouzet - BLDC SQ75 motor with integrated SMi22 CANopen drive

- 9→75 V dc, 310→600 W, 1000→1900 mNm, 1→5000 rpm *Motor only data*

- Speed, torque & postion control. CANopen network

- Holding Brake, Planetary & Worm gearboxes options available

- 2 Safe Torque Off (STO) inputs

- IP67 & IP69 as standard

Minimotor - DBS brushless servomotors with integrated drive

- Efficient and compact

- Saves seperate cable runs

- Up to 2.1Nm

- Open Bus protocols

- Reduce machine build components

Electromen - EM-269A BLDC motor 2Q drive 12-35 V dc, 2 A

- 12-24 V dc, 2 A continuous, 3 A peak

- Open & closed loop (hall sensor feedback) control operation

- Speed, direction, current limiting and soft start/stop control

- Compact, din rail mountable

Technosoft IPOS2401

Motion controller drive - 1A

- Power up to 24W, continuous and peak current 0.9A, power supply voltage 12-24VDC

- Built-in motion controller

- For brushed DC, BLDC and stepper motors

- Communication RS-232 (TMLCAN) and CANopen (default) or EtherCAT (optional)

- Open PCB design

Definox - Pigging Valves and Systems

Valves and systems

- Developed from hygienic guidelines

- Primary use for Pigging systems

- The valves are particularly suitable for CIP cleaning

- For processes with high viscosity, fast curing media

- Definox® offers a fully integrated valve solution

Jung HYGHSPIN series pump

Hygienic twin scew pump

- Flow 30l/h to 300 m³/h

- Pressure up to 35 bar

- Viscosity up to 1,000,000 cSt

- Temperature -10°C to +130°C (180°C)

- Max. particle size 45mm

Jung HYGHSPIN double flow series

Hygienic twin screw pump

- Flow rate 1m³/h to 30m³/h

- Pressure up to 50 bar

- Viscosity up to 1,000,000 cSt

- Temperature -10°C to +130°C (160°C)

- Mx. particle size 19mm

Anderson Negele - Inductive conductivity sensor, 3A

ILM-4 with I/O Link

- Direct measurement of concentration

- temperature compensated

- 4-20 mA conductivity / temperature outputs

- Fast temperature response time. T90, 15 ... 60 s

- Built-in display

Anderson Negele Turbidity Sensor ITM-51

ITM-51 & ITM-51R

- Infrared Backscatter Principle

- Measuring Range > 2000 NTU (> 500 EBC)

- Operating Pressure Max 16 Bar

- Approvals: FDA; 3-A

IDEM Non-contact RFID locking switch MGL Stainless Steel

- Heavy or medium duty holding force

- Available in 316 grade stainless steel

- Operates with most safety relays to achieve up to PLe/Cat.4

- RFID master coded or unique coding

IDEM - Safety non-contact switch CMC-F

- Stainless steel housing

- Mounting screws from the bottom

- For demanding food applications

- Switching range - 14 mm

- No dedicated controller

IDEM Stainless steel IP69K guard locking switch KL3-SS-P2L

- Power to lock; spring to unlock mechanism

- Slim stainless steel body

- Suitable for applications where immediate unlocking is required

- IP69K enclosure protection

- 8 actuator entry positions

IDEM - Stainless steel IP69K guard locking switch KLT-SS-RFID

- Anti-tamper tongue technology

- Mirror polished Ra10 Stainless Steel 316

- Will fit on 73mm fixing centres

- IP69K

- LED diagnostics for Solenoid, lock/faults

Duelco HR-2007F Two Hand Control Relay

- Safety Category 4 / Performance level e

- Type IIIC (EN 574)

- Status-/fault indication via LEDs

- 2 NO safety outputs

- Available with 230VAC and 24V AC/DC supply voltage

Kubler Slip ring SR085B

- Compact modular system

- Speed max. 200 rpm

- Lifespan 500 million revolutions

- two-chamber system

Kubler Slip ring SR120

- Modular system

- Ethernet compatible

- Transfer speed up to 100 Mbps

- Shielded metal casing

Datalogic Matrix 320 Imager

- 2MP imager

- Detects 1D and 2D code types

- Frame rates up to 60fps

- Integrated communication via Ethernet 10/100/1000Mbit/s, Serial RS232/RS422FD, OPC UA

Computar VSW Series ViSWIR Lens

SWIR lenses Lite

- Designed for Visible + SWIR Imaging Sensors!

- Available in 5…50mm focal lengths

- 1/2" and 2/3" sensor size

- Designed for C mount cameras

Basler Racer Line Scan Cameras

GigE & Cameralink Line Cameras

- 2 k to 12 k resolution and Up to 80 kHz Line Rate

- Supported by Pylon Suite software and open-source SDKs for easy image acquisition and fast application development

- Monochrome Cameras

- GigE Vison and Camera Link Interface Compatible

- Lens Mount: C-mount & F-mount

Datasensing P2x series smart camera

The Datasensing P2x smart camera offers precise vision-guided robotics with advanced pattern matching and easy installation. Its compact design simplifies maintenance for industrial inspection

- qHD (960x540) or 2MP (1920x1080) resolutions

- Interchangable lenses(upto 7.5mm), illuminators(36 or 14LED) and filters

- Mono or colour CMOS image sensors

- Rotating connectors

- Powered by IMPACT software

Datasensing SMART-VS

Smart sensor based on machine learning

- The first smart sensor based on Machine Learning

- Ease of use and installation

- Up to 150mm operating distance

- AI enabled and MLAS - Machine Learning Assisted Setting

- **PLUS version now available**

.jpeg?mh=450&mw=450&hash=27E2293124F0795A5849E890819BC825)

.jpeg?mh=450&mw=450&hash=1DC35F9F1B8479CD153C10ABF112631A)