IO LINK – COMMUNICATION WITH SENSORS AND ACTUATORS

IO-Link is the first interface for communication with sensors and actuators and is an international standard.

At OEM Automatic, we are involved in the development of the automation industry, and we want to help you develop and streamline your process. This article explains IO-Link in detail and the products that we offer.

WHAT IS IO-LINK?

In short, IO-Link is an interface that simplifies communication with sensors and actuators.

What makes IO-link different to other interfaces?

IO-Link is different from most similar interfaces as it is standardised internationally, making this their most prominent feature.

So, there is no need to think about whether different components from different manufacturers are compatible.

How IO-Link works

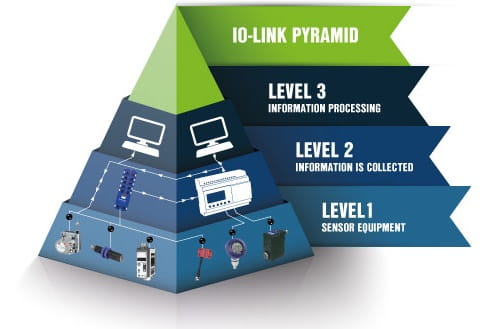

The pyramid below shows how different products can communicate to the same master, which passes this information on to software, which then refines the information. It is also possible to send information directly from sensor level to software.

Blog

LEVEL 3: THE INFORMATION IS PROCESSED / SENT

The information from level 1 or 2 is used to make calculations regarding efficiency, operating time and future maintenance with the help of software, that compiles the information. From here, you can also control and configure your devices further down the chain.

LEVEL 2: INFORMATION COLLECTED

Information is collected with the help of a master. For example, a PLC can be placed in the industry, this means that you do not have to configure your long wiring to the machine level. You can also configure the sensors remotely, so you don't have to go out to the site to adjust the settings.

LEVEL 1: SENSORS

Smart sensors in the industry communicate information to level 3 efficiently thanks to IO-Link. The sensors can also be configured remotely, making the products "Smart".

5 ADVANTAGES OF IO-LINK

- IO-link allows you to collect information from your sensors and enables you to configure them remotely.

- During maintenance, it is easy to time-efficiently replace the product with the same settings as the replaced product.

- You want to avoid unplanned downtime, and once you plan to stop production, you want the opportunity to replace several products at the same time.

- With the help of IO-link, you can see the status of your products. In addition, the simplicity of IO-link means that fewer errors occur when the system is connected.

- Thanks to the IO-link interface, all products can collaborate regardless of brand, saving time and resources on integration and translations between different protocols.

Reduce costs

Get your full potential

increase productivity

efficient maintenance

IO-LINK AT OEM AUTOMATIC

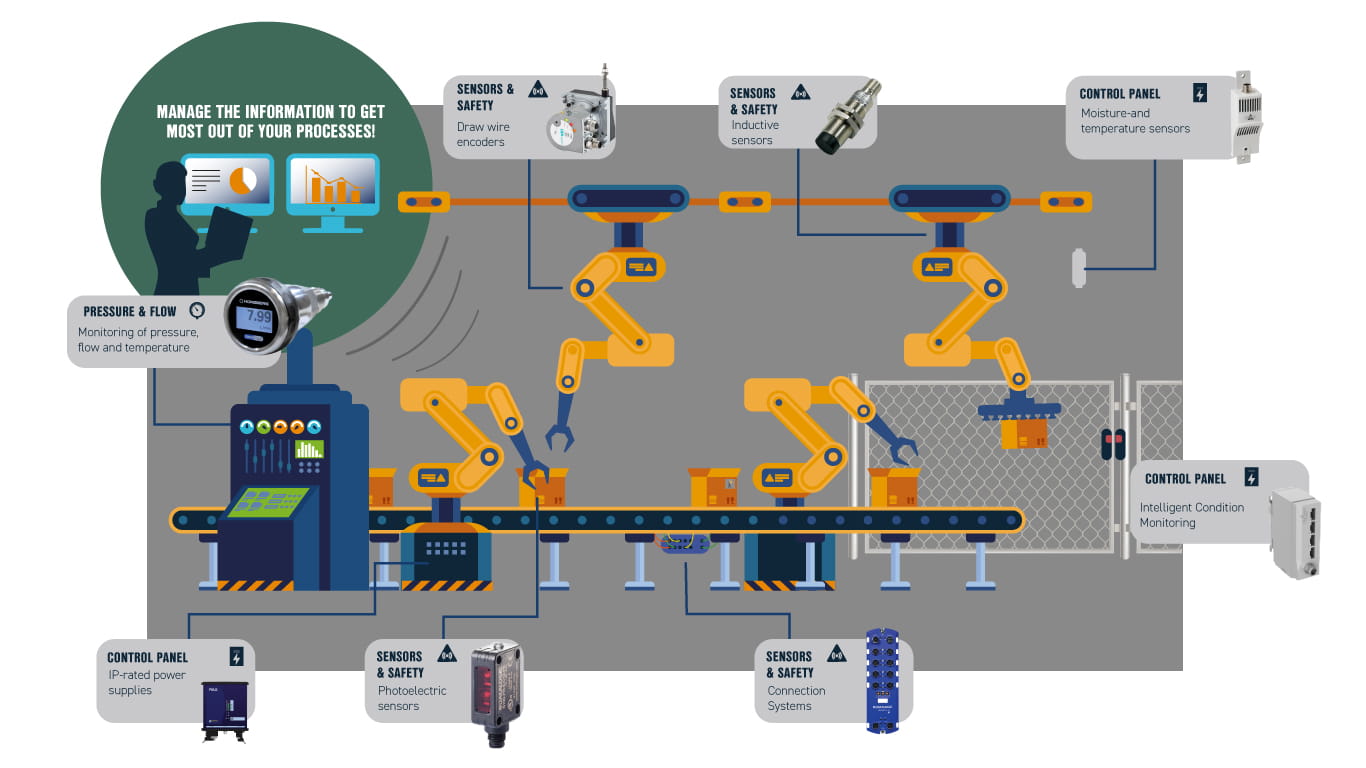

At OEM Automatic, you will find a wide range of different IO-Link products, cutting-edge knowledge in different areas, and a partner who has a great understanding of integration.

PRODUCTS

OEM Automatic has many different products under one roof and product managers who are professionals within their areas.

In addition to knowledge, we also have a great interest in developing the industry and want to offer you the best products for you and your process.

KNOWLEDGE

In addition to our extensive range of products, we have product managers who possess good competence for their products. Behind our product managers are our manufacturers, who are happy to help in more complex projects.

INTEGRATION

We collaborate with partners that add a lot of knowledge and experience with integration, which is about connecting different smart products that can deliver information. You also want to manage this information to benefit your process and configure your products.

WIDE RANGE AND EXPERIENCE

There are many opportunities to streamline your industry with us. Below you see our range of IO-Link products.

Power Supplies

A power supply is the heart of every application. Via IO-Link, the power supply communicates the status so that you can plan maintenance, avoid downtime, and perform troubleshooting faster.

Temperature and Regulation

Smart Sensor CSS 014 is a compact humidity and temperature sensor from STEGO that combines three functions in one: the sensor, interface, and transmitter. This sensor uses the latest microtechnology and microsystem technology used in intelligent sensors of small sizes. Compatible with STEGO CONNECT for the integration of analogue devices.

Inductive Sensors

Inductive sensors are used for position indication, impulse, or motion sensors for metal objects. The inductive sensor lacks moving parts and is therefore suitable for applications with a high contact frequency.

The switching signal, parameter-diagnostic and communication data are transmitted by using a point-to-point connection. The inductive sensors can be configured in IO-Link mode and then used in IO-Link or SIO (Standard IO mode).

How does your process benefit from IO-link in these products?

Optimize energy consumption and prevent downtime

Optimize energy consumption and prevent downtime

Get data for all different components in the same device

Get data for all different components in the same device

Set breakpoints in the unit easily through display or program via IO-Link

Set breakpoints in the unit easily through display or program via IO-Link

Integrated data logging that can be used to save operational data

Integrated data logging that can be used to save operational data

When it comes to sensors, each can be parameterised by independent manufacturers of IO-Link masters

When it comes to sensors, each can be parameterised by independent manufacturers of IO-Link masters

When replacing components, the device automatically identifies and configures itself

When replacing components, the device automatically identifies and configures itself

You are IIoT ready!

You are IIoT ready!

FLOW TEMPERATURE, PRESSURE AND LEVEL MONITORING

Monitoring is an integral part of the process. We have a wide range of flow, temperature, pressure and level monitoring instrumentation with IO-Link and can help you find the products that are best suited for your application and process.

PROPORTIONAL VALVES

By controlling pressure with proportional valves, you can regulate the speed of pistons and the power of pneumatic press tools with IO-Link proportional valves.

HYGIENIC VALVES

We offer a wide range of hygienic valves with IO-Link developed for economic flow control, for example, the biotechnology, brewery, food, and dairy industries. Our range covers some of the different valves you may need in your process.

Turbidity Sensor

In food production, media is usually analysed to keep track of, for example, concentrated concentration and turbidity in the process. We offer IO-Link turbidity sensors to measure conductivity and turbidity in liquid media.

Related Products

Smart sensor - CSS 014

CSS

- High Accuracy

- 4-20mA Temperature & Humidity outputs

- Compact DIN or screw mount

- M12 Quick connect socket

- IO-Link version

Stego Connect

SCE, SCM, SEN

- Intelligent Condition Monitoring

- Temperature, Humidity, Pressure, Luminosity and Distance Sensors

- Compatible with Smart Sensor CSS 014

- IO-Link hubs

- Cloud based

Anderson Negele - Inductive conductivity sensor, 3A

ILM-4 with I/O Link

- Direct measurement of concentration

- temperature compensated

- 4-20 mA conductivity / temperature outputs

- Fast temperature response time. T90, 15 ... 60 s

- Built-in display

Anderson Negele Turbidity Sensor ITM-51

ITM-51 & ITM-51R

- Infrared Backscatter Principle

- Measuring Range > 2000 NTU (> 500 EBC)

- Operating Pressure Max 16 Bar

- Approvals: FDA; 3-A

Honsberg OMNIPLUS-F Flow Sensor

- for liquids upto 100 Bar

- Flow range 0.02 to 3 m/s

- Connection type from Push-in to threaded G1/2

- IO-Link interface

Datalogic IO-Link Master CBX-8IOL

IO-Link Connection Box

- 8 M12 IO-Link ports to PROFINET or ETHERNET IP

- IP67 Housing

- PLC access to IO-Link ISDU blocks

- Web server user interface

DATASENSING TL46 contrast sensor with RGB LED

Now available in IO-Link

- Wide spectrum with RGB LED

- Color mode enhanced model (TL46-WE)

- Fastest and accurate low jitter model (TL46-WJ)

- PNP/NPN output, now available in IO-Link

- Rotatable 5 position M12 connector

DATASENSING - S100 - Miniature sensor

IO-link versions now available

- Miniature photoelectric sensor

- Front and back mounting holes

- 2m embedded cable or M8 connector

- PNP, NPN or IO-link output

- Light on/dark on selectable through wires

DATASENSING - S8 - Miniature photoelectric sensor

IO-link versions available

- Compact size (14 x 42 x 25mm)

- M8 Connector or M12 Pig-tail

- Available in IP69K stainless steel

- LED or laser emission

- Now with IO-link versions

DATASENSING - S65-M - Distance sensor

- Range up to 5m with Time of Flight technology

- Infrared LED for detection, green LED for alignment

- PNP/NPN outputs

- I/O link models available

- IP67 protection