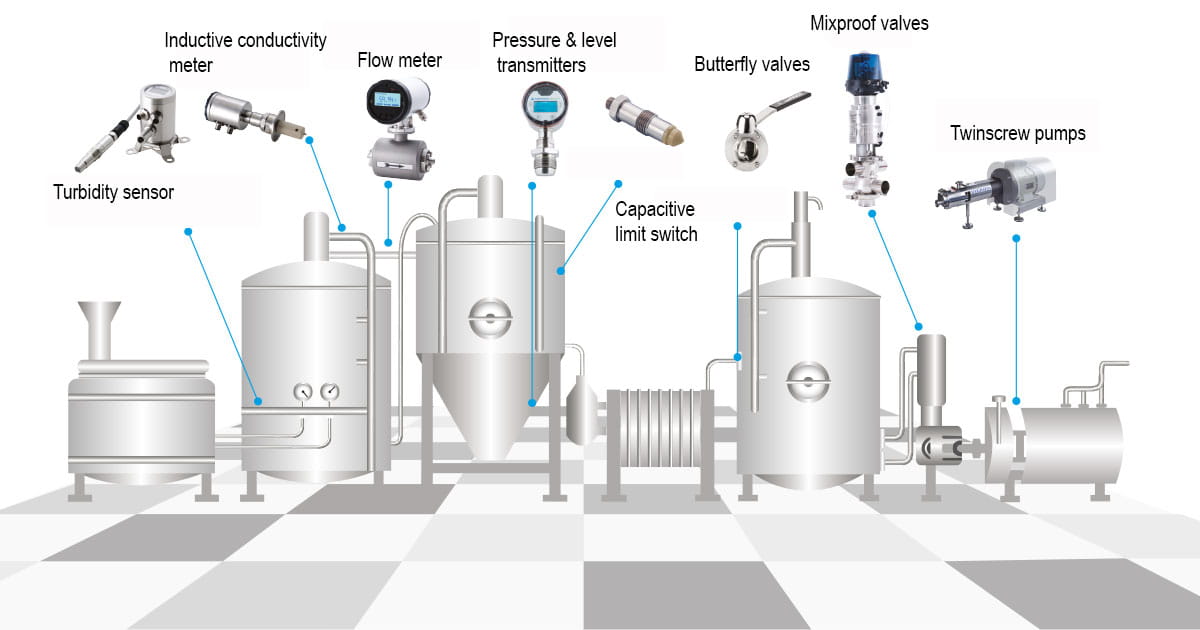

Essentials for your production line - Process Management Systems

The instrumentation below measures and controls the pressure, flow and level of liquids and gases within the production line. We aim to help you save money and reduce waste on your production line using this range of selected products.

JUNG PROCESS SYSTEMS – HYGHSPIN TWIN-SCREW PUMPS NEW

Jung Process Systems - OEM's first-ever pump supplier, have been specialists in hygienic twin-screw pumps since 2009. The new Hyghspin Twin-Screw Pumps are described in three words as hygienic, gentle and economic and we are proud to announce Jung Process Systems as an addition to our pressure and flow product range!

The main advantage of the Jung Hyghspin twin-screw series is that it enables efficient, hygienic and optimally adapted transport and production processes.

Hyghspin twin-screw Pumps can be suited to a wide range of applications, including:

- Emptying of containers

- Transfer within tank plants

- Transfer within production processes (supply, pressure boosting, discharge)

- Metering and filling

Why add Hyghspin twin-screw pumps to my production line?

- Highly efficient – can use free-flowing products of virtually any consistency

- Good suction capacity, carefully handling all free-flowing products in volumes up to 300 m³ / h

- Service friendly – compatible with CIP systems

- Space-saving design

- Outstanding flexibility and pulsation-free flow

- Used for both pumping and cleaning of the product

Approvals

Jung Process Systems is internationally certified by EHEDG, 3-A (USA) and Atex, required by the food industry.

You can read more about the new Hyghspin Pump Series and why they have become our first pump supplier here.

Jung's Related Products

Jung HYGHSPIN series pump

Hygienic twin scew pump

- Flow 30l/h to 300 m³/h

- Pressure up to 35 bar

- Viscosity up to 1,000,000 cSt

- Temperature -10°C to +130°C (180°C)

- Max. particle size 45mm

Jung HYGHSPIN Hopper series pump

Hygienic twin screw pump

- Flow 100l/h to 30m³/h

- Pressure up to 25 bar

- Viscosity up to 50,000,000 cSt

- Temperature -10°C to +130°C (160°C)

- Max. particle size 45mm

Jung HYGHSPIN extended series pump

Hygienic twin screw pump

- Flow 100l/h to 350m³/h

- Pressure up to 6 bar

- Viscosity up to 1,000,000 cSt

- Temperature -10°C to +130°C (180°C)

- Max. particle size 67mm

Jung HYGHSPIN double flow series

Hygienic twin screw pump

- Flow rate 1m³/h to 30m³/h

- Pressure up to 50 bar

- Viscosity up to 1,000,000 cSt

- Temperature -10°C to +130°C (160°C)

- Mx. particle size 19mm

Jung HYGHSPIN Engineered series

Hygienic twin screw pump

- Flow 30l/h to 350m³/h

- Pressure up to 50 Bar

- Viscosity up to 1,000,000 cSt

- Temperature -10°C to +130°C (180°C)

- Max. particle size 67 mm

As well as pumps, we can supply and advise on several process management products which will help optimise your production line.

See our recommended products below:

INDUCTIVE CONDUCTIVITY SENSOR BY ANDERSON-NEGELE

Inductive conductivity meter ILM-4

With the ILM-4, it is possible to directly measure the concentration of a medium that can effectively improve the CIP cleaning process and be economically advantageous. Suitable for product quality monitoring too.

Why add this inductive conductive meter to my production line?

- Saves water and time

- Saves time due to fast temperature response time

- Improves CIP time spent increasing efficiency

- Inline conductivity is cost-effective

Approvals:

FDA; 3-A

MAGNETIC-INDUCTIVE FLOW METER BY ANDERSON-NEGELE

The FMI Magnetic Inductive Flow Meter from Anderson-Negele is designed for highly accurate flow rate and volumetric measurement of fluids and pastes for customers from the food- and pharmaceutical industries. It has a measuring range of 0.1...10 m/s and operating pressure is 0.1.

Why add this magnetic-inductive flow meter to my production line?

High volume measurements due to Inductive flow

Long life span due to multi-proof and corrosion resistant

Superior accuracy ±0,2 % ±1 mm/s and reproducibility also with a low flow rate

Vacuum proof so pigging system can be cleaned with a flow meter in place, making it hygienic too

Approvals:

FDA; 3-A

CAPACITIVE LIMIT SWITCH BY ANDERSON-NEGELE

NCS-11

The capacitive limit switch limits detection of media with low or no water content like syrup, fruit concentrates, alcohols and oils with a dielectric constant εr (Dk) ≥ 2. With a measuring range of Dk ≥ 20 and an operating pressure maximum of 10 bar.

Why add this capacitive limit switch to my production line?

- Alternative to vibration forks

- Compact size and easy to clean

- Extended measuring range

- Very quick response time

- Large number of process connections, e.g. CLEANadapt and tri-clamp

Approvals:

FDA; EHEDG; 3-A

TURBIDITY SENSORS: ITM-51, ITM-51-R BY ANDERSON-NEGELE

Anderson-Negeles' front-flush turbidity sensor is for low to high turbidities, with an IO-Link for media with a turbidity of 200… 300.000. We can offer sensors with different measuring methods for almost any application.

Why add turbidity sensors to my production line?

- Minimisation of resource losses

- Flex-hybrid: digital IO-Link and analog 4…20 mA in parallel

- Modular design: configurable from the low-cost, basic version to the high-end model

- Front-flush sensor: simplified pipe cleaning (pigging possible) ideal for media with adhesive fibres or particles

- Extended temperature and pressure range

- Independent to reflexions at small diameters or electro-polished

- High reproducibility and fast response time

- Selectable output value

- Active phase separation in production process, e.g. dairies

- Reduction of the water consumption and waste water treatment cost

- Minimisation of the duration of a CIP (cleaning process)

- No colour dependency

L3 PRESSURE AND LEVEL TRANSMITTER BY ANDERSON-NEGELE

Anderson-Negeles' L3 Pressure and Level Transmitter has been designed to measure process pressure or hydrostatic level in hygienic process applications.

Why add a pressure and level transmitter to my production line?

- Improved temperature compensation

- High accuracy also with turndown up to 1:10

- Accurate level measurement also in small containers and with rapidly changing process temperatures

- Modular design for individual configuration, with Smart Replace Design (easy component exchange in the field)

- Integrated tank linearisation with density compensation for high-precision output of volume or mass (kg, litres, percent)

- Easy adjustment of zero and span

Anderson Negele Related Products

Anderson Negele - Inductive conductivity sensor, 3A

ILM-4 with I/O Link

- Direct measurement of concentration

- temperature compensated

- 4-20 mA conductivity / temperature outputs

- Fast temperature response time. T90, 15 ... 60 s

- Built-in display

Anderson Negele Magnetic-Inductive Flow Meter FMI

FMI

- Magnetic-Inductive

- Measuring Range 0.1...10 m/s

- Operating Pressure 0.1...11 bar absolute

- Approvals: FDA; 3-A

Anderson Negele - Capacitive level switch - Food NCS

NCS-01, NCS-02, NCS-11, NCS-12, NCS-L

- Capacitive limit switch

- Measuring range Dk ≥ 20

- Operating pressure max 10 bar

- Approvals: FDA; EHEDG; 3-A

Anderson Negele Turbidity Sensor ITM-51

ITM-51 & ITM-51R

- Infrared Backscatter Principle

- Measuring Range > 2000 NTU (> 500 EBC)

- Operating Pressure Max 16 Bar

- Approvals: FDA; 3-A

HYGIENIC BUTTERFLY VALVES BY DEFINOX - DPX AND DPAX

Typically, you would see butterfly valves like this used for brewing, dairy production, food, chemical and cosmetics. The DPX & DPAX range of butterfly valves from Definox are available from DN 25 to DN 150,

Why add this hygienic valve to my production line?

- Reliable and economical technology

- Quick installation and removal

- Can be used anywhere, many different types of gaskets

- Low pressure drop

- Product flow without media retention

MIXPROOF VEOX with IO LINK BY DEFINOX

VEOX INNOVATIVE MIX PROOF VALVE

The VEOX Mixproof valve meets the strongest process technology requirements and is the ideal solution for Food, Brewery, Cosmetic processes.

The valve is fitted with two valve seats, each with a "floating" PFA seal in a particular slot that makes the valve extremely easy to clean.

When the valve opens, the "floating" PFA seal allows cleaning also in the track behind the PFA seal.

The Mixproof valve is also available as a tank outlet valve which isolates the tank from the rest of the process.

The shape of the body and the valve seat ensures that the flow can be maintained with the same functions as floating gaskets.

Why add the Mixproof valve to my production line?

- Leak indicator for leakage between gaskets

- New seal ensures high performance and long life

- Fast, easy service

- Leak-free opening available

- Complete tightness with sliding gaskets avoiding product loss

- The elastomeric structure of the PFA seal also ensures that the surface is not porous and does not develop cracks, also highly resistant to chemical media.

PIGGING VALVES AND SYSTEMS BY DEFINOX

Definox Pigging Valve:

The pigging valve and system has been developed according to hygienic guidelines for the high standards of process technology and based on the same design principle as Definox' other valves.

The main applications of a pigging valve are for the pigging system.

Definox Pigging Systems:

Pigging systems are ideally suited for processes with high viscosity and fast hardening media, e.g. yoghurt, dressing, cheese, chocolate, toothpaste, etc.

Why add this pigging system to my production line?

- With the Definox pigging valve, you get a complete integrated valve solution.

- Easy maintenance and quick installation.

- The valves are particularly suitable for CIP cleaning

- Additional sources of contamination of valve and pipe system are eliminated

Definox Related Products

Definox - DPX and DPAX

- Reliable and economical technology

- Quick installation and removal

- Can be used anywhere, many different types of gaskets

- Low pressure drop

- Product flow without media retention

Definox - MixProof VEOX

- New innovative design

- Leak indicator, for leakage between gaskets

- New seal ensures high performance and long life

- Fast, easy service

- Mixproof valve with multi body.

Definox - Pigging Valves and Systems

Valves and systems

- Developed from hygienic guidelines

- Primary use for Pigging systems

- The valves are particularly suitable for CIP cleaning

- For processes with high viscosity, fast curing media

- Definox® offers a fully integrated valve solution

For more information see our Process Management Solutions page.

Alternatively contact our Pressure & Flow department, where our Product Specialists are waiting to help you with your enquiry: [email protected] or call us on 0116 284 9900

.jpeg?mh=450&mw=450&hash=27E2293124F0795A5849E890819BC825)

.jpeg?mh=450&mw=450&hash=1DC35F9F1B8479CD153C10ABF112631A)