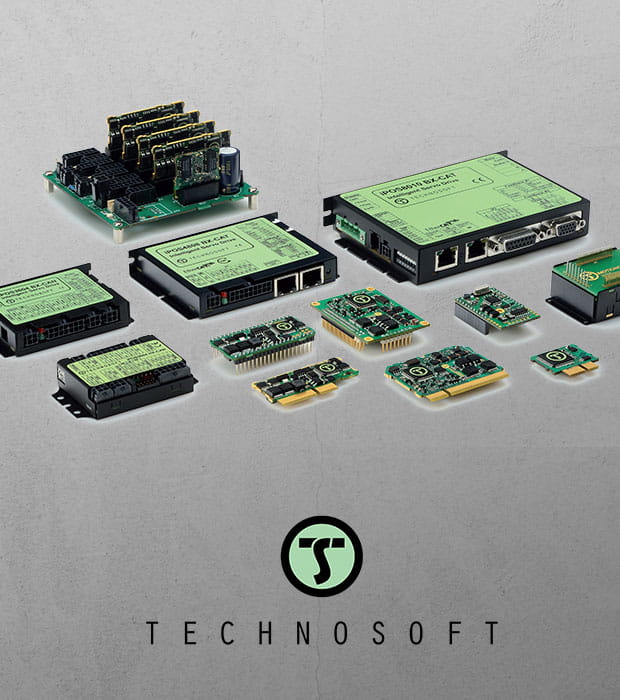

Technosoft specialise in developing intelligent drives and certainly live up to the term 'intelligent’, by combining a powerful motor and motion controller to implement complex movements.

One of the leading names in motors and drives, Oriental Motor, has signed a distribution deal with OEM Automatic. OEM Automatic can support customers, especially where an AC or Brushless DC (BLDC) motor has been discontinued or proving hard to source.

The Simplex Motion integrated servomotor is a brushless DC motor with integrated electronics and outrunner rotor. You can now browse Simplex Motion servomotors on our website.

OEM Automatic currently offers PMW’s range of standard pancake motors, as well as its bespoke design service. PMW’s motor portfolio caters for customers requiring both brushed and brushless configurations, supplied as housed or frameless, for both geared and direct drive applications.

DOGA’s new 311 and 311E is a right angle geared motor range, available with or without an integrated drive offering CANopen compatibility,

Smela offers a compact electric alternative to pneumatic cylinders, thanks to OEM Automatic’s exclusive partnership with SMELA – it is now available in the UK.

DC traction motors are typically used in applications where some form of vehicle propulsion is required. See our Doga and Siboni range and their uses here!

DOGAs’ 359 series is the next generation of the current 259 series of DC gear motors. In this article, we take a look at the key characteristics of the original 259 model and outline the features offered by the 359 series.

How do economical motors save you costs? With brushless technology, both the performance and life expectancy are considerably longer than brushed DC alternatives...

The DBS line from Mini Motor stands out as it is a compact, self-contained motor, absolute encoder and drive.