Design considerations for EV charging stations

With the growth in electric vehicle sales, EV charging is in demand. Charging stations are appearing around the country and slowly becoming a part of new life. There are now more than 42,000 charge point connectors across the UK, and the option of having your own charging station at home is also becoming increasingly popular.

With the increase in demand for consumers to have home charging stations and electric cars, we should see an increase in the amount of new EV charging businesses on the market. So, what goes into an EV charging station?

You may use some of the following panel components in your EV charging stations if you are a manufacturer. It is important to have the most effective components within your EV charging station to contribute towards a user-friendly, aesthetically pleasing and highly efficient investment.

To give you an idea, we will talk about some of the components that make up an EV charging station.

What Components are found in an EV Charging Station?

BEACONS / DUAL COLOUR BEACON (image 1)

Dual coloured beacons are used for a visual indication of status, for example, you may use green and red to show the level of battery charge. Another example includes using the colours to indicate whether the charger is free to use and red for not in use.

The I series range is available in 3 sizes to suit all applications.

Aesthetically, a beacon would be beneficial. You can use the dual colour beacons to notify users of any indicators as our R-Series range has seven different colours to use.

Diffusers can also be used with your beacon to reduce the brightness in particular environments, such as home charging stations.

Cable entry systems (image 2)

Cable entries are an ideal solution where pre-assembled cables and conduits are being used in charging stations and power distribution panels and where space is restricted.

Most cable entry systems consist of only 3 parts, and the feed-through openings can be adapted to your charging station requirements.

Why the ContaClip KDS is suitable for EV applications?

- Prevent dust

- 1mm to 35mm diameter cables or conduits

- Easy to mount and tool free

- Space-saving

- IP66 protection

- Options for round or flat cables for feeding into the enclosure

Heaters and Fans (image 3 and 5)

Depending on the size, location, and type of charging station, various heating and cooling components may be required. You must optimise the temperature within the system to prevent low temperatures and condensation, which could damage electrical components.

We recommend Stego’s heating solution range, which ensures equal distribution of warm air.

You may require compact or flat convection heaters, or for larger enclosures (distribution panels), there are higher powered fan heaters available, which can also be used for cooling by simply turning off the heater.

Facts about heaters:

- Compact sizes available for smaller enclosures

- Self-regulating

- Versions with built-in thermostat

We also recommend adding built-in DIN rail thermostats to monitor to use with your heating and cooling systems. Not forgetting ‘touch safe’ housings.

Blog

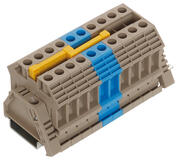

TERMINAL RAILS (image 4 and 7)

Terminal rails are the backbone of electrical control systems. These devices will secure two or more wires together and are enclosed in safe insulated housing.

Terminal rails increase safety and protect other components in the charging station, making them essential for EV charging stations.

Why the ContaClip screw terminals SRK (image 4) are suitable for EV applications?

- Can cater for cable sizes 0.2mm² to 240mm²

- Feed-through terminals

- Screw-connection mechanism easy to operate and safe

- Pluggable cross connectors up to 35mm²

- 1000V rated

- Material polyamide 6.6 - UL94-V0

- Temperature resistance -40 ºC...+120 ºC

- Phase colours for easy wiring identification

Why the ContaClip push in terminals PRK (image 7) are suitable for EV applications?

- Can cater for cable sizes 0.2mm² to 16mm²

- Feed-through terminals

- 2 to 4 connections

- 2-way cross-connect channel

- Push-button cable release

OEM can supply pre-assembled terminal rails to your specification, and this can save time on installation and reduce the number of parts required to be stocked.

EMC CABLE GLANDS (image 6)

You would typically find cable glands inside the charging station for supply and ancillary signalling cables.

The use of EMC glands prevents any external interference from entering the station and disrupting any of the electronics and communications.

Using a cable gland compensates for tolerances in shielding thicknesses and ensures a secure and reliable connection to the cable screen.

Watch the video below:

Why is the EMC cable gland suitable for EV applications?

- Optimal spring clip shield contact

- Quick and easy assembly

- Stainless versions on request

- -60°…+100°C

- IP68 up to 10 bar, IP69

Enclosures (image 8)

Enclosures are used to protect valuable electrical components within the EV charging station from the outside elements, as well as protecting users.

Choosing a high-quality, robust enclosure can improve the aesthetics of your EV charging station. They can be made to order in a range of sizes and colours to fit with your brand image.

Depending on the type of charging station, whether it be a home or public charging station, you would require a particular type of enclosure. Polycarbonate enclosures would be used for external EV charging systems.

OEM Automatic can supply bespoke, tailored enclosures to your exact specification. We can work with you on the size, material, colour, type and branding of the enclosure.

OEM can provide custom built DIN rail assemblies, profiled enclosures and kitted parts through our well equipped technical workshop to optimise your build time and reduce stock holding.

This article was designed to help people and companies who are interested in designing and building EV charging stations. Our panel team are on hand to answer any questions you may have regarding EV charging or any of the components mentioned above.

Call us on 0116 284 9900 or email [email protected].

Related Products

Beacons

Cable Entry Systems

EMC Glands

Filter Fans

Convection Heaters

Fan Heaters

Thermostats

Enclosures

Screw Terminals