Barcode Scanner Technology: Choosing The Right Technology For Your Application

What is a Barcode Scanner?

Barcode scanners, also known as barcode readers, are essential devices used to translate the information contained within barcodes into data, which is then sent to a computer or processing system.

These devices work by emitting light, detecting the reflection, decoding the information, and transmitting the data for use in various applications such as inventory management, logistics, and retail.

Learning hubHow Barcode Scanners Work:

- Light Emission: A barcode scanner projects light (usually red) onto the barcode.

- Light Detection: A sensor inside the scanner detects the light reflected back from the barcode's dark bars and light spaces.

- Decoding: Internal circuitry analyses the pattern of the reflected light and translates it into digital data.

- Data Transmission: The decoded data is then transmitted to a connected computer system for processing.

Some modern scanners are also capable of reading QR codes, 1D and 2D barcodes, postal codes, and stacked codes, providing even greater flexibility across industries.

Core Components and Features of Barcode Scanners:

Core Components:

All barcode scanners need 4 basic components to provide suitable functionality for scanning in any environment or application.

- Light Source: Typically LEDs or laser diodes that illuminate the barcode.

- Lens System: Focuses the emitted light onto the barcode and collects the reflected light.

- Photosensor: Detects the reflected light and converts it into an electrical signal.

- Decoder: Processes the electrical signals and interprets them as readable data.

Additional Features:

Depending on the model and intended environment, barcode scanners may also offer:

- Connectivity Options: Such as Bluetooth, wireless communication, or USB connections.

- Durability: Models designed for industrial use can withstand drops, dust, and harsh environments.

- High Scanning Speeds: Ensures faster reading and processing of large volumes of barcodes.

- Extended Battery Life: A critical feature for wireless and portable scanners.

Common Applications For Barcode Scanners:

Barcode scanners are versatile and support a wide range of applications, offering efficiency, easy identification, and streamlined management of inventory and processes. Examples include:

Real-time tracking of inventory levels, movements, and locations, ensuring accurate record-keeping and stock management.

Facilitating the identification and monitoring of equipment, tools, and materials, helping to optimise resource utilisation and reduce loss.

Monitoring product movement through manufacturing processes, ensuring quality standards are met and processes are traceable.

Enhancing order management and delivery tracking, improving accuracy and customer satisfaction.

Barcode scanners form the primary component of retail point of sale systems, for accurate scanning and quick access to product information.

Contact Us With Your Application

These are just a few examples; barcode scanners can be employed in an even wider array of sectors and tasks.

If you need help with an application contact the experts at OEM Automatic's Sensors & Safety Department - 0116 284 9900 or email [email protected]

Key Considerations When Choosing a Barcode Scanner:

When selecting the right barcode scanner for your application, consider:

Distance and Speed:

Long-range scanning or high-throughput environments may benefit from laser scanners or fast imagers.

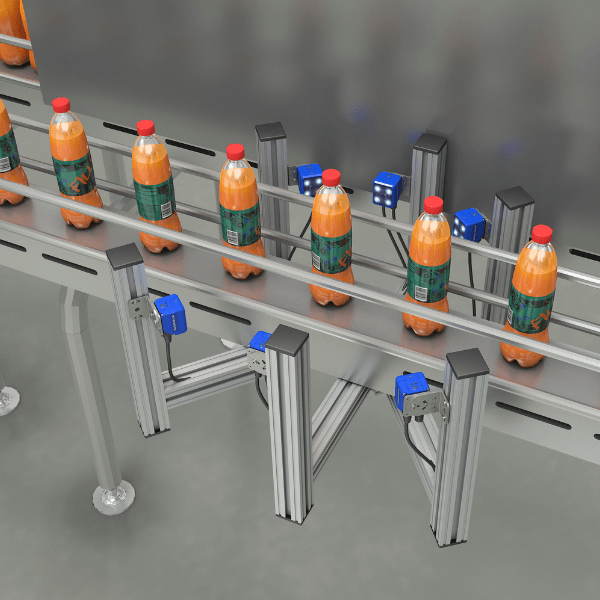

High speed

Captures fast-moving barcodes on conveyors or production lines, perfect for high-speed logistics and manufacturing.

Suitable scanner: Datalogic Matrix 320

Low speed

Affordable and reliable for low-speed retail or office environments, offering simple setup and consistent performance.

Suitable Scanner: Datalogic Quickscan QW2500

Short range

Optimized for close-range, high-precision barcode scanning, especially in compact self-service or ticket validation units.

Suitable scanner: Datalogic Blade

Long range

Auto Range model capable of reading barcodes from just a few centimetres up to several meters away

Suitable scanner: Datalogic Powerscan PBT9501-AR

Functionality:

Handheld Scanners:

Designed for flexibility and mobility, allowing the user to move the scanner to the barcode.

Suitable scanner: Datalogic Gryphon GBT4500

Fixed Scanners:

Permanently mounted, these scanners are used for continuous or automated scanning in production lines.

Suitable scanner: Datalogic Blade

Industrial Handheld Scanners:

Ruggedised versions of handheld scanners, built to endure harsh conditions such as extreme temperatures, dust, and frequent drops.

Suitable scanner: Datalogic Powerscan 9600

OEM and Embedded Scanners:

Designed to be integrated directly into kiosks, turnstiles, vending machines, and industrial equipment, offering high performance in compact form factors.

Suitable scanner: Datalogic DE2011-DL OEM Scan Engine

Technology:

Laser Scanners:

Utilise a laser beam to reflect off the barcode and detect the bars and spaces. Laser scanners are ideal for fast, long-range scanning and are generally best suited for reading 1D barcodes.

Suitable scanner: Datalogic DS5100 Laser Scanner

CCD Scanners (Charge-Coupled Device):

Capture images of barcodes using an array of tiny light sensors. They offer high-speed scanning but are typically limited by the size of the scanning area.

Suitable scanner: Datalogic Gryphon I GD4200

Image Scanners (2D Area Imagers):

Use a miniature camera to capture the full image of the barcode. They can read both 1D and 2D codes, including damaged or poorly printed barcodes, making them extremely versatile.

Suitable scanner: Datalogic AV500/AV900 Series

Environmental factors

Lighting and reflective surfaces:

Insufficient or uneven lighting can make it difficult to read barcodes, as well as reflective surfaces creating glare. 2D imagers work best in these environments.

Suitable scanner: Datalogic Matrix 320 2D Imager

Dirt, dust and damage:

Obscuring barcodes and potentially causing damage to equipment due to build up. Industrial barcode scanners are most suitable in these environments due to their extra dust protection, ruggedised build and drop protection.

Suitable scanner: Datalogic PowerScan 9600

Barcode quality:

Printing errors, size, contrast and printing quality can all impact how well a scanner can read a barcode.

Suitable scanner: Datalogic Matrix 320 2D imager

Connectivity Requirements:

Choose between wired and wireless models based on your operational needs.

Wired

Offers USB, Ethernet, and serial interfaces, perfect for integration into fixed production or inspection systems.

Suitable scanner: Datalogic Matrix 320

Wireless

Wireless scanner using Datalogic’s STAR Cordless System™, suitable for mobile workers in industrial environments.

Suitable scanners: Datalogic Powerscan PM9600

Bluetooth

Connects via Bluetooth to mobile devices and PCs for flexible, untethered scanning in offices, healthcare, and point-of-sale setups.

Suitable scanner: Datalogic Gryphon GBT4500

Ease of Integration:

Compatibility with existing systems and software is crucial for smooth deployment.

Suitable scanner: Datalogic Blade series and Datalogic Quickscan QBT2400.

Choosing a trusted Barcode Scanner

OEM Automatic offers an extensive range of barcode scanners from leading manufacturer Datalogic, tailored for diverse industrial applications. Whether you require handheld, fixed, or rugged scanners, we have the solutions to meet your specific requirements.

Our product specialists can help you identify the ideal scanner technology for your project, ensuring optimum performance and reliability across your operations.

Need Help with a Barcode Application?

Our Sensors & Safety Team is here to help! Whether you need expert advice, product recommendations, or a proof-of-concept demonstration:

Phone support – Call us at 0116 284 9900

Email support – Contact us at [email protected]

Live chat – Available on our website

On-site visits – Our expert sales engineers can provide in-person demos and application support. Email [email protected] to arrange a visit or call us.

Let us help you find the right barcode scanner for your application. Contact us today!

related products

Handheld Scanners

Industrial Scanners

1D Laser Scanners

2D scanners