How do I know if I need a pressure switch or a pressure sensor?

When choosing between a pressure switch and a pressure sensor, the key lies in understanding your application and how you intend to monitor or control pressure within your system. Choosing the right device helps avoid over-engineering or under-protecting your process.

Learning hubPressure Switches – How Do They Work?

A pressure switch is a device that monitors and controls pressure in industrial systems by opening or closing a circuit once a specified pressure level is reached.

- Sensing: Pressure switches use sensing elements such as diaphragms or pistons to detect changes in gas or fluid pressure.

- Switching: When the predefined pressure is reached, the sensing element activates a switch, opening or closing a circuit.

- Control: This switching action can control various functions, such as starting/stopping pumps, adjusting compressors, or triggering safety alarms.

Pressure Sensors – How Do They Work?

A pressure sensor (also known as a pressure transducer or pressure transmitter) measures the pressure of a gas or fluid and converts it into an electrical signal, typically received by a PLC or controller.

- Sensing: Pressure sensors measure the force exerted by the media on a sensing element, often a diaphragm.

- Conversion: This force is converted into an electrical signal (voltage or current) sent to a control system, such as a PLC.

- Control: The signal transmitted to a control system enables automated monitoring or control of processes, based on measured pressure.

Key differences between pressure switches and pressure sensors

| Feature | Pressure Switches | Pressure Sensors |

| Functionality | On/off control - opens or closes a circuit | Continuous pressure measurement |

| Output | Binary output (above / below threshold) | Continuous analogue or digital signal (e.g. 4-20mA, 0-10 V) |

| Applications | Simple control systems | Advanced monitoring and control system |

| Types | Mechanical or electrical | Diaphragm, capacitive, piezoresistive, etc |

| Cost | Simpler design - lower cost | Higher cost due to increased functionality |

Typical Applications Of Pressure Switches & Pressure Sensors

When choosing between a pressure switch and a pressure sensor, understanding their real-world applications can help clarify which is right for your system.

Pressure Switch Applications – Simple, Reliable Control

Pressure switches are ideal for systems that need on/off control based on pressure thresholds.

Industrial Equipment: Common in air compressors, refrigeration units, and filtration systems to automate pressure control and trigger alerts.

Machinery & Flow Systems: Used in wastewater treatment and pipeline control for system safety.

Vehicles: Monitor oil pressure and regulate air suspension systems.

Buildings: Found in HVAC units, water pumps, wells, and boiler systems to protect equipment and maintain consistent pressure.

Specialised Uses: Also used in medical oxygen systems, agricultural spraying, and marine water systems.

Pressure Sensor Applications – Data-Driven Precision

Pressure sensors are best for applications requiring continuous monitoring and accurate readings.

Industrial Monitoring: Essential in manufacturing, oil & gas, and water treatment for tracking and optimising pressure in real time.

Automation & HVAC: Enable precise control of actuators, hydraulics, and airflow systems.

Transport & Aerospace: Measure pressure in tyres, fuel, oil, and braking systems, as well as in aircraft cabins and hydraulics.

Medical & Robotics: Support critical functions in ventilators and robotic movement with high precision.

Emerging Tech: Used in renewable energy (hydrogen, wind) and environmental monitoring (air quality, groundwater).

Smart Buildings: Enhance building automation through pressure data in fire suppression and HVAC systems.

Summary

A pressure switch is ideal for simple on/off control based on a defined pressure threshold. It's typically used in pump control, alarm systems, and safety shutdowns where complex monitoring is unnecessary.

A pressure sensor, on the other hand, provides continuous pressure data, making it suitable for real-time monitoring, data logging, and integration into control systems like PLCs and SCADA. It’s the better choice for applications where pressure trends and precision are critical.

Consider your system's requirements and complexity:

Top Tip!

- Use a pressure switch for simple on/off control.

- Use a pressure sensor for real-time pressure feedback, trending, or automation integration

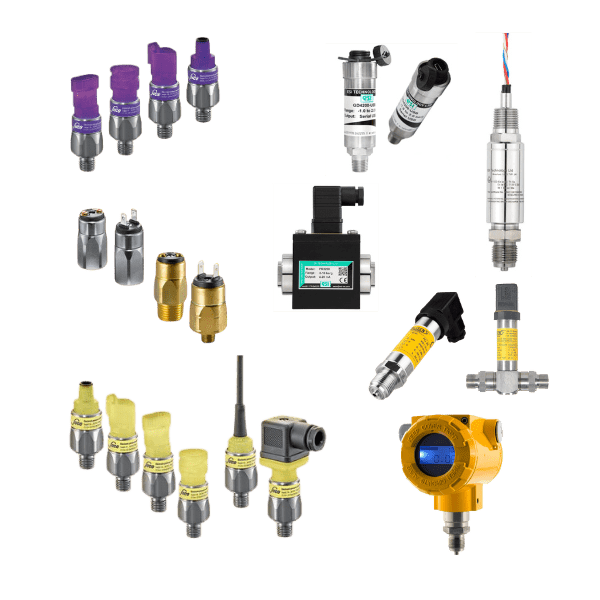

Choosing a Trusted Manufacturer

At OEM Automatic, we supply high-quality Pressure Sensors & Pressure Switches from trusted manufacturers including Suco, ESI & Aplisens. Each product is carefully selected to meet the diverse safety requirements of industrial applications.

Our pressure monitoring specialists are here to help you select the right switch or sensor, based on your specific use case.

Need Help with a pressure monitoring application?

Our Pressure & Flow team is ready to assist with expert advice, product recommendations, and proof-of-concept support.

Phone: 0116 284 9900

Email: [email protected]

Live Chat: Available on our website

Onsite Support: Book a visit from one of our experienced engineers for demonstrations and application advice - email [email protected] to arrange a visit

Let us help you find the right technology for your application. Contact us today.

Related products

Mechanical Pressure Switches

Electrical Pressure Switches