ANDERSON NEGELE

Anderson Negele Magnetic-Inductive Flow Meter FMQ

FMQ

The FMQ Magnetic Inductive Flow Meter from Anderson-Negele is ideal for flow rate and volumetric measurement of fluids and pastes for customers from the Food- and Pharmaceutical industries. Meeting the high expectations of these industries with regard to accuracy, life span and cleaning, the FMQ is also low maintenance and is available with all necessary certification.

The precise degree of accuracy at low flow rates permits the FMQ to be used in dosing and filling systems, where the media has a conductivity of 5 μS/cm and can also be used to monitor media with a < 5 % solid particle content (where the media has the same level of conductivity).

The sensor is made entirely of 316 stainless steel, with all of the media contacting materials being FDA approved. The FMQ is suitable for CIP-/SIP-cleaning up to max. 130 °C (up to 30 minutes) and also has an automatic empty pipe detection, to protect other components in your system from dry running damage. With a simple user interface that doesn’t need the housing opening to adjust the parameters, moisture ingress, care and maintenance are all minimised. This is accompanied by a vacuum tight metering tube that is rigid, even at high temperatures and is also piggable.

Application Examples:

- Magnetic-inductive flow meter for the measurement of flow rate and volume in food and pharmaceutical applications

- Suitable for liquids, mash and pastes with a minimum conductivity of 5 μS/cm

- Precise measurement of media containing solids (< 5 % solid particle content)

- Measurement range from 30 l/h to 640 000 l/h

- Suitable for dosing and filling applications

- DN10-DN150 sizes available

- Optional surface finish on metal process connection Ra ≤ 0.4 μm (Pharma)

- FDA Certified

OEM Automatic can get the FMQ flowmeter to you in 3 working days!

The FMQ electromagnetic flow meter is an extremely versatile, robust and reliable device for all conductive media.

Specifications for instant delivery (other options available at standard lead time):

- Measuring range from 30 l/h to 300 000 l/h

- Measuring accuracy: ±0,5% ±2mm/s

- DN 10…100 available on stock

- Flex-Hybrid Technology with easy programming via display or PC

- Magnetic-Inductive

- Measuring Range 0.1...10 m/s

- Operating Pressure 0.1...11 Bar Absolute

- Approvals: FDA; 3-A

Selected variant

Technical data

| Approvals | FDA |

|---|---|

| Area of apllication | Food, Pharma |

| IP class | IP67 |

| Material display | PMMA |

| Material electrode | Stainless steel 316L |

| Material of connection | Stainless steel 316L |

| Material of seals | EPDM food approved |

| Material of sensor housing | Stainless steel AISI 304 |

|---|---|

| Material of wetted parts | PFA |

| Temperature ambient from | -25 °C |

| Temperature ambient to | 60 °C |

| Temperature of media from | 0 °C |

| Temperature of media to | 100 °C |

Product description

The FMQ Magnetic Inductive Flow Meter from Anderson-Negele is ideal for flow rate and volumetric measurement of fluids and pastes for customers from the Food- and Pharmaceutical industries. Meeting the high expectations of these industries with regard to accuracy, life span and cleaning, the FMQ is also low maintenance and is available with all necessary certification.

The precise degree of accuracy at low flow rates permits the FMQ to be used in dosing and filling systems, where the media has a conductivity of 5 μS/cm and can also be used to monitor media with a < 5 % solid particle content (where the media has the same level of conductivity).

The sensor is made entirely of 316 stainless steel, with all of the media contacting materials being FDA approved. The FMQ is suitable for CIP-/SIP-cleaning up to max. 130 °C (up to 30 minutes) and also has an automatic empty pipe detection, to protect other components in your system from dry running damage. With a simple user interface that doesn’t need the housing opening to adjust the parameters, moisture ingress, care and maintenance are all minimised. This is accompanied by a vacuum tight metering tube that is rigid, even at high temperatures and is also piggable.

Application Examples:

- Magnetic-inductive flow meter for the measurement of flow rate and volume in food and pharmaceutical applications

- Suitable for liquids, mash and pastes with a minimum conductivity of 5 μS/cm

- Precise measurement of media containing solids (< 5 % solid particle content)

- Measurement range from 30 l/h to 640 000 l/h

- Suitable for dosing and filling applications

- DN10-DN150 sizes available

- Optional surface finish on metal process connection Ra ≤ 0.4 μm (Pharma)

- FDA Certified

OEM Automatic can get the FMQ flowmeter to you in 3 working days!

The FMQ electromagnetic flow meter is an extremely versatile, robust and reliable device for all conductive media.

Specifications for instant delivery (other options available at standard lead time):

- Measuring range from 30 l/h to 300 000 l/h

- Measuring accuracy: ±0,5% ±2mm/s

- DN 10…100 available on stock

- Flex-Hybrid Technology with easy programming via display or PC

Ordering information

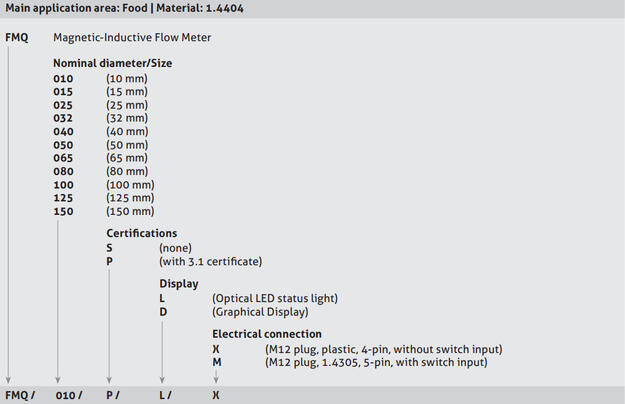

Please refer to the image below for ordering information.

Related

Water & Wastewater Solutions

OEM Automatics water and wastewater application specialists have gathered all our solutions in one place. Our products are used in everything from small municipal water works to larger regional plants.

understanding viscosity - And Why It Matters When Choosing A Pump

Whether you’re pumping water, chocolate, oil or peanut butter knowing the product’s viscosity is essential to selecting the right pump. Find out more about viscosity and which pump may be suitable for your application!

Float switches built to perform and ready to ship

Whether you're looking to upgrade your current solution or secure a more robust float switch for your next project, Taurus delivers performance you can count on.

How do I know if I need a pressure switch or a pressure sensor?

When choosing between a pressure switch and a pressure sensor, the key lies in understanding your application. Our Pressure Monitoring experts breaks down the two devices for you.

We offer air diaphragm pumps by SAMOA

Pumps are now officially part of our product offering! As we build our pump portfolio, we’re proud to announce that we are an official distributor of SAMOA Industrial, a well-established name in the fluid handling industry.

Barcode Scanner Technology: Choosing The Right Technology For Your Application

OEM Automatic's barcode scanner experts have broken down barcode technology to help you choose the right scanner for your application!