ANDERSON NEGELE

Anderson Negele - Calorimetric Flow Switch

Calorimetry is the industry standard for flow switching/monitoring in food processing, utilising pulsed heating technology to determine a flow rate these sensors are lower cost option for flow monitoring, where more expensive and accurate options are simply unnecessary. The Anderson Negele FTS is built to the highest standards, is made completely from stainless steel and is designed specifically for hygienic applications as you would expect. With a flow optimised tip design to reduce the probes impact on media flow, the FTS also has a short response time and is insensitive to temperature shocks in your system.

The FTS also has a self protection built in, should it see high temperatures to protect it against thermal damage. It turns itself off and has a self reset once the temperature has reduced to a safe level. With an optional digital display to show you what percentage of your flow range is taking place in your application, there is a local indication of when the desired flow rate has been reached via an LED and the device has a switched PNP output for feeding in to your PLC.

Application Examples:

- Flow monitoring in pipes from DN 25

- Dry-run pump protection

- Filter monitoring

- Agitators

- Cooling loops

- Suitable for highly pure, aqueous media without particles or solids (e.g. ultra-filtered media, cola)

- FDA Certified

- Caliormetric Measuring Principle

- Measuring Range 10…300 cm/s

- Operating Pressure Max 60 bar

- Approvals: FDA; EHEDG; 3-A

Selected variant

Technical data

| Approvals | FDA |

|---|---|

| Area of apllication | Food |

| Flow area max | 2 m/s |

| Flow area min | 0.1 m/s |

| IP class | IP69K |

| Material cover | Polycarbonate |

| Material of sensor housing | Stainless steel 1.4308 |

| Material of wetted parts | Stainless steel 316L |

| Pressure range max | 10 bar |

|---|---|

| Response time | 5000 ms |

| Surface finish | 0.8 µm Ra |

| Temperature ambient from | -20 °C |

| Temperature ambient to | 70 °C |

| Temperature of media from | 0 °C |

| Temperature of media to | 100 °C |

Product description

Calorimetry is the industry standard for flow switching/monitoring in food processing, utilising pulsed heating technology to determine a flow rate these sensors are lower cost option for flow monitoring, where more expensive and accurate options are simply unnecessary. The Anderson Negele FTS is built to the highest standards, is made completely from stainless steel and is designed specifically for hygienic applications as you would expect. With a flow optimised tip design to reduce the probes impact on media flow, the FTS also has a short response time and is insensitive to temperature shocks in your system.

The FTS also has a self protection built in, should it see high temperatures to protect it against thermal damage. It turns itself off and has a self reset once the temperature has reduced to a safe level. With an optional digital display to show you what percentage of your flow range is taking place in your application, there is a local indication of when the desired flow rate has been reached via an LED and the device has a switched PNP output for feeding in to your PLC.

Application Examples:

- Flow monitoring in pipes from DN 25

- Dry-run pump protection

- Filter monitoring

- Agitators

- Cooling loops

- Suitable for highly pure, aqueous media without particles or solids (e.g. ultra-filtered media, cola)

- FDA Certified

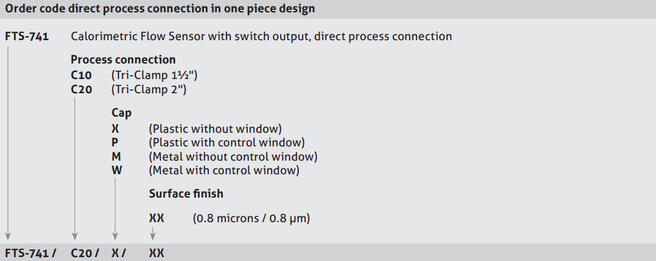

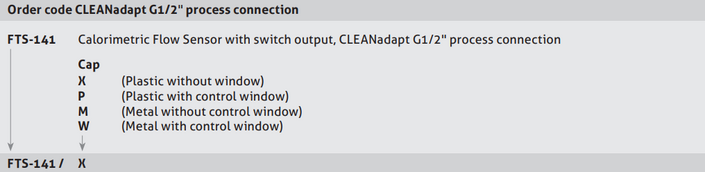

Ordering information

Please refer to the image below for ordering information.

Related

Water & Wastewater Solutions

OEM Automatics water and wastewater application specialists have gathered all our solutions in one place. Our products are used in everything from small municipal water works to larger regional plants.

understanding viscosity - And Why It Matters When Choosing A Pump

Whether you’re pumping water, chocolate, oil or peanut butter knowing the product’s viscosity is essential to selecting the right pump. Find out more about viscosity and which pump may be suitable for your application!

Float switches built to perform and ready to ship

Whether you're looking to upgrade your current solution or secure a more robust float switch for your next project, Taurus delivers performance you can count on.

How do I know if I need a pressure switch or a pressure sensor?

When choosing between a pressure switch and a pressure sensor, the key lies in understanding your application. Our Pressure Monitoring experts breaks down the two devices for you.

We offer air diaphragm pumps by SAMOA

Pumps are now officially part of our product offering! As we build our pump portfolio, we’re proud to announce that we are an official distributor of SAMOA Industrial, a well-established name in the fluid handling industry.

Barcode Scanner Technology: Choosing The Right Technology For Your Application

OEM Automatic's barcode scanner experts have broken down barcode technology to help you choose the right scanner for your application!