ANDERSON NEGELE

Anderson Negele Pressure sensor DAN-HH

DAN-HH

We market high quality printing and design from our supplier Anderson-Negele, which meets the highest standards of process engineering, and is the perfect solution for applications for food, pharmaceuticals, breweries, cosmetics and pharmaceutical processes.

The products of Anderson-Negele are manufactured according to the concept "Hygienic by Design", which is reflected in the special process adapters: CLEANadapt and PHARMadapt as well as the unique design of the instruments.

Pressure sensor, type DAN-HH -...

This unit uses a built-in piezoelectric converter to convert the process value into a corresponding mV signal. The mV signal then passes through a customer-specific linearization and signal processing. The resulting signal corresponds to industry standard 4 ... 20 mA. This mA signal is factory-set for this unit's measurement range. For relative pressure sensors, the back of the membrane is ventilated; that is, this sensor measures the mean pressure and / or vacuum relative to air pressure.

For an absolute pressure sensor, the measured value is relative to a perfect theoretical vacuum. This means that the signal changes with the air pressure for the respective environment.

Other features:

· CIP / SIP cleaning up to 150 ° C

· Product-related materials are FDA-compatible

· Stainless steel sensor and product-related materials

· Additional process connections in combination with CLEANadapt: Flange (DIN 11851), VARIVENT, m.f.

Please contact us for more information and price.

- Pressure measurement in pipes and containers

- High temperatures up to 150 ° C

- Front-flush, hygienic and easily sterilizable installation with EMZ-352 or EHG -... / 1 "connection

- Complies with 3-A Sanitary Standard 74-06, Third Party Verified (Only with Tri-Clamp Mount)

- EHEDG-certified hygienic CLEANadapt process connection

Selected variant

Technical data

| Approvals | 3-A, FDA |

|---|---|

| Area of apllication | Food |

| IP class | IP69K |

| Material of sensor housing | Stainless steel AISI 304 |

| Material of wetted parts | Stainless steel 316L |

| Measurement range | 0 ... 34 bar rel., -1 ... 13 bar rel. / 0 ... 20 bar abs. |

| Supply voltage dc max | 36 V DC |

| Supply voltage dc min | 12 V DC |

|---|---|

| Surface finish | 0.6 µm Ra |

| Temperature ambient from | -20 °C |

| Temperature ambient to | 50 °C |

| Temperature of media from | 0 °C |

| Temperature of media to | 150 °C |

Downloads

Product description

We market high quality printing and design from our supplier Anderson-Negele, which meets the highest standards of process engineering, and is the perfect solution for applications for food, pharmaceuticals, breweries, cosmetics and pharmaceutical processes.

The products of Anderson-Negele are manufactured according to the concept "Hygienic by Design", which is reflected in the special process adapters: CLEANadapt and PHARMadapt as well as the unique design of the instruments.

Pressure sensor, type DAN-HH -...

This unit uses a built-in piezoelectric converter to convert the process value into a corresponding mV signal. The mV signal then passes through a customer-specific linearization and signal processing. The resulting signal corresponds to industry standard 4 ... 20 mA. This mA signal is factory-set for this unit's measurement range. For relative pressure sensors, the back of the membrane is ventilated; that is, this sensor measures the mean pressure and / or vacuum relative to air pressure.

For an absolute pressure sensor, the measured value is relative to a perfect theoretical vacuum. This means that the signal changes with the air pressure for the respective environment.

Other features:

· CIP / SIP cleaning up to 150 ° C

· Product-related materials are FDA-compatible

· Stainless steel sensor and product-related materials

· Additional process connections in combination with CLEANadapt: Flange (DIN 11851), VARIVENT, m.f.

Please contact us for more information and price.

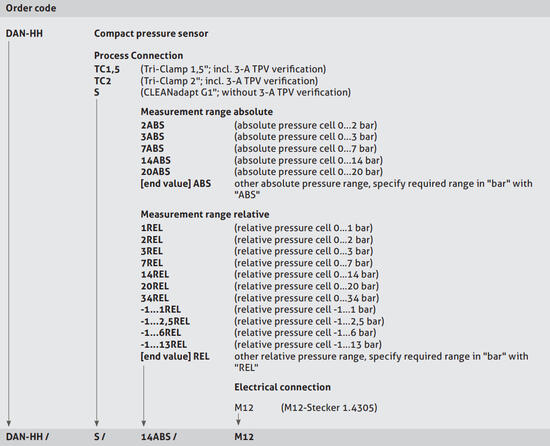

Ordering information

Please refer to the image below for ordering information.

Related

Water & Wastewater Solutions

OEM Automatics water and wastewater application specialists have gathered all our solutions in one place. Our products are used in everything from small municipal water works to larger regional plants.

understanding viscosity - And Why It Matters When Choosing A Pump

Whether you’re pumping water, chocolate, oil or peanut butter knowing the product’s viscosity is essential to selecting the right pump. Find out more about viscosity and which pump may be suitable for your application!

Float switches built to perform and ready to ship

Whether you're looking to upgrade your current solution or secure a more robust float switch for your next project, Taurus delivers performance you can count on.

How do I know if I need a pressure switch or a pressure sensor?

When choosing between a pressure switch and a pressure sensor, the key lies in understanding your application. Our Pressure Monitoring experts breaks down the two devices for you.

We offer air diaphragm pumps by SAMOA

Pumps are now officially part of our product offering! As we build our pump portfolio, we’re proud to announce that we are an official distributor of SAMOA Industrial, a well-established name in the fluid handling industry.

Barcode Scanner Technology: Choosing The Right Technology For Your Application

OEM Automatic's barcode scanner experts have broken down barcode technology to help you choose the right scanner for your application!