ANDERSON NEGELE

The Anderson-Negele HM-E is a turbine inductive flow meter of very high build quality and is designed to be simple and easy to maintain with a two part housing that is simple to disassemble and clean. It is constructed from 316L stainless steel to offer a high resistance to aggressive media and has Rulon™ bearings to match the body material for media compatibility. This meter is an FDA approved alternative to paddle wheel and variable area meters where the media is of a low viscosity and it can also work with non conductive media, where a magnetic inductive flow meter would not be possible to use.

The H-ME flow meter is a compact size and comes with process connections you would expect for a hygienic instrument with the nominal widths according to ASME BPE and DIN 11850 Series 2. The output is a pulsed frequency for easy volumetric measurement and comes in sizes from ¾” up to 2”. There are options for an analogue output and also a display should you need a live indication of your flow rate. It has a built in flow conditioning system to reduce wear on the components and improve accuracy whilst lowering pressure drop across the sensor. This is an accurate and fast responding sensor that is ideal for use with such media as filtered fruit juice or beer, alcohols, light oils, saline solutions, cleaning agents and acids.

Application Examples & Design Features:

| Approvals | 3-A, FDA |

|---|---|

| Area of apllication | Food |

| IP class | IP69K, NEMA Type 4X |

| Material chain | Stainless steel AISI 304 |

| Material of rotor | Stainless steel 316L |

| Material of seals | PTFE |

| Material of sensor housing | Stainless steel AISI 304 |

| Material sensor | Stainless steel 316L |

| Material storage | Rulon 123™ |

|---|---|

| Pressure range max | 10 bar |

| Surface finish | 0.8 µm Ra |

| Temperature ambient from | -40 °C |

| Temperature ambient to | 85 °C |

| Temperature of media to | 150 °C |

The Anderson-Negele HM-E is a turbine inductive flow meter of very high build quality and is designed to be simple and easy to maintain with a two part housing that is simple to disassemble and clean. It is constructed from 316L stainless steel to offer a high resistance to aggressive media and has Rulon™ bearings to match the body material for media compatibility. This meter is an FDA approved alternative to paddle wheel and variable area meters where the media is of a low viscosity and it can also work with non conductive media, where a magnetic inductive flow meter would not be possible to use.

The H-ME flow meter is a compact size and comes with process connections you would expect for a hygienic instrument with the nominal widths according to ASME BPE and DIN 11850 Series 2. The output is a pulsed frequency for easy volumetric measurement and comes in sizes from ¾” up to 2”. There are options for an analogue output and also a display should you need a live indication of your flow rate. It has a built in flow conditioning system to reduce wear on the components and improve accuracy whilst lowering pressure drop across the sensor. This is an accurate and fast responding sensor that is ideal for use with such media as filtered fruit juice or beer, alcohols, light oils, saline solutions, cleaning agents and acids.

Application Examples & Design Features:

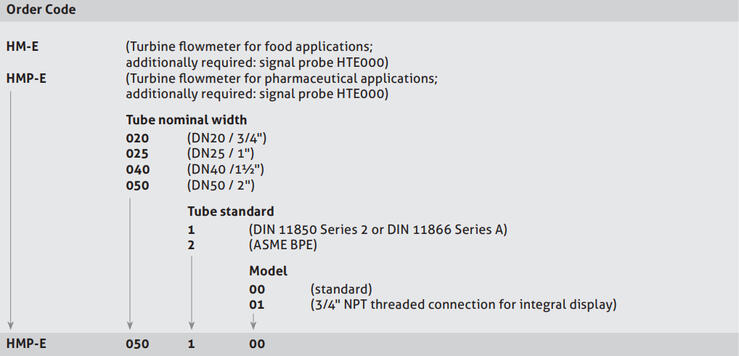

Please refer to the image below for ordering information.

OEM Automatics water and wastewater application specialists have gathered all our solutions in one place. Our products are used in everything from small municipal water works to larger regional plants.

Whether you’re pumping water, chocolate, oil or peanut butter knowing the product’s viscosity is essential to selecting the right pump. Find out more about viscosity and which pump may be suitable for your application!

Whether you're looking to upgrade your current solution or secure a more robust float switch for your next project, Taurus delivers performance you can count on.

When choosing between a pressure switch and a pressure sensor, the key lies in understanding your application. Our Pressure Monitoring experts breaks down the two devices for you.

Pumps are now officially part of our product offering! As we build our pump portfolio, we’re proud to announce that we are an official distributor of SAMOA Industrial, a well-established name in the fluid handling industry.

OEM Automatic's barcode scanner experts have broken down barcode technology to help you choose the right scanner for your application!

|

|

|

|

|

|

||

|---|---|---|---|---|---|---|

|

|

|

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

| Parts | Area of apllication | Surface finish | Price | ||

|---|---|---|---|---|---|

Art:

HM-E

Copied

|

Food

|

0.8 µm Ra

|

| ||

Art:

HMP-E

Copied

|

Pharma

|

0.5 µm Ra

|

|

Select a variant in the list