Setting up light curtains & Barriers

Did you know that you can set up light curtains and barriers yourself? We'll guide you through the process.

WHAT IS LIGHT CURTAIN OR LIGHT BARRIER?

A light curtain or light barrier, also often referred to as safety light curtains, act like an invisible fence, designed to protect people from coming into contact with dangerous machines or moving parts. They are photoelectric safety devices which provide protection from hazardous machinery and are capable of monitoring large areas.

Light curtains consist of a transmitter and receiver. From the transmitter, infrared beams are transmitted to the receiver. When one or more of the light beams are interrupted, a dual output stop signal is given to stop the dangerous action of the machine.

HOW TO SET UP A LIGHT CURTAIN OR LIGHT BARRIER

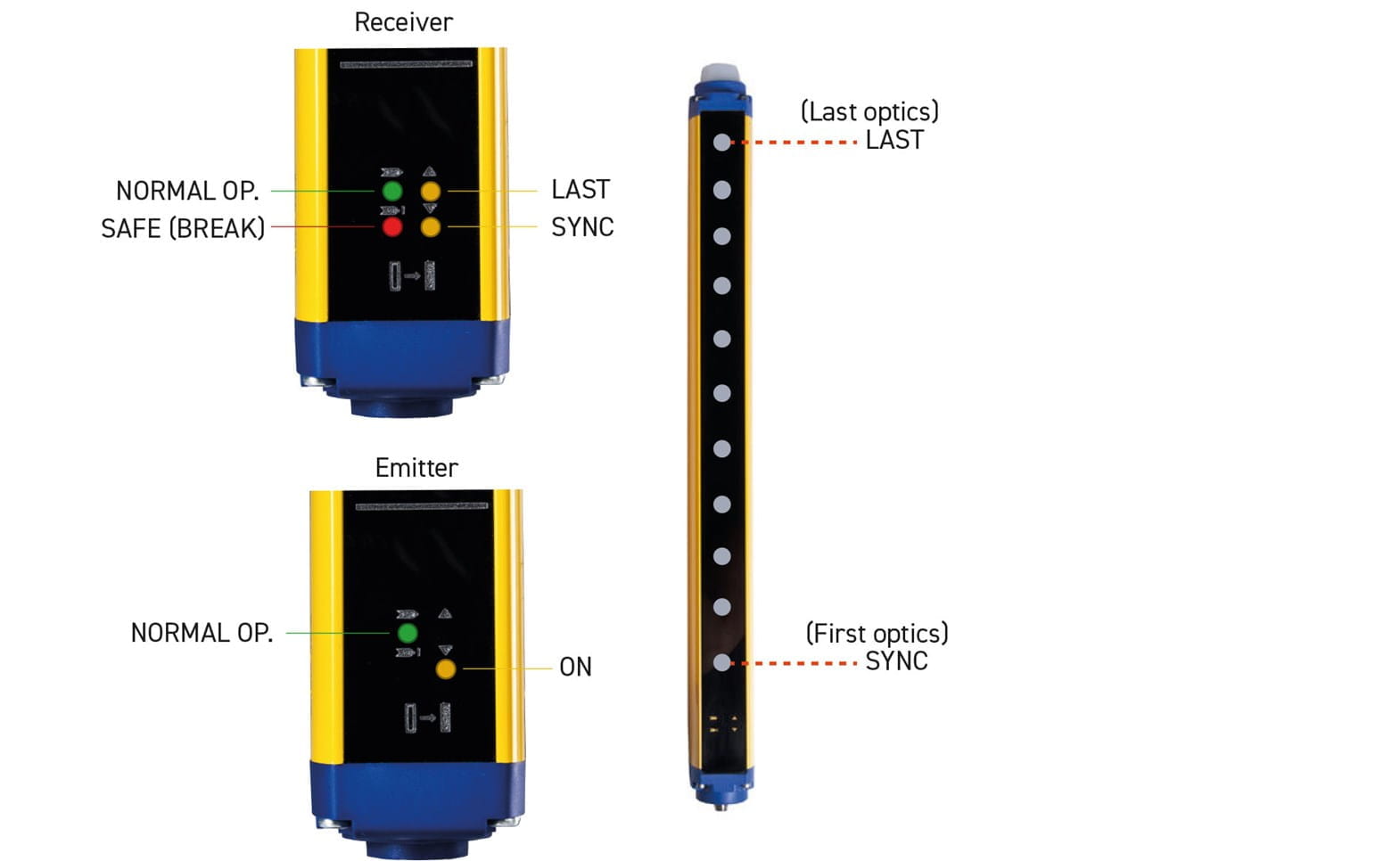

Alignment between the transmitter and receiver is necessary for the light curtain to function properly. Good alignment prevents instability of the output caused by dust or vibrations. The alignment is perfect if the optical axes of the first and last beams of the transmitter coincide with the optical axes of the receiver. The beam used to synchronise the two units is the one closest to the bottom. SYNC is the optic connected to this beam and LAST is the optic connected to the last beam after the SYNC unit.

Learning hub

CORRECT ALIGNMENT PROCEDURE

The alignment adjustment can only be performed after the mechanical installation and electrical connections have been completed. Then follow the procedure below:

NOTE : The system that informs the user of the obtained alignment is located on the receiver. The alignment function can be activated when the unit is turned on by keeping the normally open RESET/RESTART switch closed for at least 0.5 seconds.

A. Fix the receiver in a stable position and adjust the transmitter until the yellow LED (SYNC) is OFF. This indicates the correct alignment of the first beam (synchronization beam).

1. Rotate the transmitter, swinging on the last optical axis, until the yellow LED (LAST) is OFF. NOTE: Make sure the green LED (NORMAL OP.) is constantly lit.

2. Define the area where the green LED (NORMAL. OP) is lit steadily by making some micro adjustments - for the first and then for the second unit - to obtain maximum alignment (4) and then place both units in the center of this area.

3. Secure the two units securely with the brackets. Verify that the green LED (NORMAL OP) on the RX unit is ON and the beams are not broken. Then verify that the red LED lights up if a single beam is interrupted SAFE (BREAK). This verification should be done with a cylindrical “test piece” of a size appropriate to the resolution of the unit.

4. Turn the power supply to the unit OFF and ON to return to normal mode.

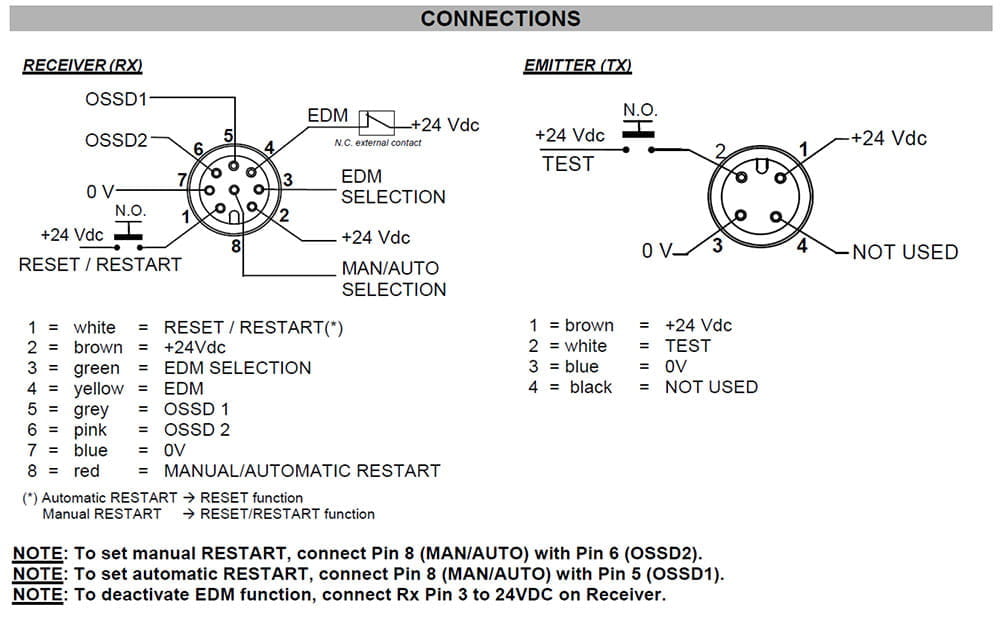

Connection Details

Choosing a Trusted Manufacturer

At OEM Automatic, we supply high-quality Safety Light Curtains & Barriers from trusted manufacturer including Datasensing (Previously Datalogic). Each product is carefully selected to meet the diverse safety requirements of industrial applications.

Our Safety specialists are here to help you select the right light curtain, based on your specific use case, they can even help you set up your light curtain.

Need Help with a safety application?

Our Sensors & Safety team is ready to assist with expert advice, product recommendations, and proof-of-concept support.

Phone: 0116 284 9900

Email: [email protected]

Live Chat: Available on our website

Onsite Support: Book a visit from one of our experienced engineers for demonstrations and application advice - email [email protected] to arrange a visit

Let us help you find the right light curtain for your application. Contact us today.

related products

Light Curtain (Finger and Hand Protection)

Light Curtain (Presence Detection)