ANDERSON NEGELE

From a diode, infrared light is radiated into the medium. The particles present in the medium reflect the incident light detected by the receiving diode (so-called backscatter method). The electronics calculate from the received signal, the relative turbidity of the medium.

The relative turbidity is given in NTU, or on the Nails calibration standard specified in "% TU" or in the EBC.

Suitable for pipe sizes as small as DN25 the versatility is broad and it has been used in many applications with great success. Not only does it help to optimise systems but the reduction in lost water, cleaning solutions and product allow it to quickly and effectively pay for itself, whilst continuing to streamline and save the end user money from the day that it is installed.

With a complete range of process connections and a remote version available there is a solution for nearly all applications where turbidity monitoring is required.

Application Examples:

| Approvals | 3-A, EHEDG, FDA |

|---|---|

| Area of apllication | Food |

| IP class | IP67, IP69K |

| Material cover | Polycarbonate |

| Material detector | Sapphire |

| Material of connection | Stainless steel 316L |

| Material of sensor housing | Stainless steel 1.4308 |

| Measurement accuracy | +/-3% - 0-999NTU ; +/- 5% > 999NTU |

| Pressure range max | 20 bar |

| Pressure range min | -1 bar |

| Response time | 750 ms |

|---|---|

| Supply voltage dc max | 32 V DC |

| Supply voltage dc min | 18 V DC |

| Temperature ambient from | -10 °C |

| Temperature ambient to | 60 °C |

| Temperature of media from | -10 °C |

| Temperature of media to | 130 °C |

| Weight | 750 g |

From a diode, infrared light is radiated into the medium. The particles present in the medium reflect the incident light detected by the receiving diode (so-called backscatter method). The electronics calculate from the received signal, the relative turbidity of the medium.

The relative turbidity is given in NTU, or on the Nails calibration standard specified in "% TU" or in the EBC.

Suitable for pipe sizes as small as DN25 the versatility is broad and it has been used in many applications with great success. Not only does it help to optimise systems but the reduction in lost water, cleaning solutions and product allow it to quickly and effectively pay for itself, whilst continuing to streamline and save the end user money from the day that it is installed.

With a complete range of process connections and a remote version available there is a solution for nearly all applications where turbidity monitoring is required.

Application Examples:

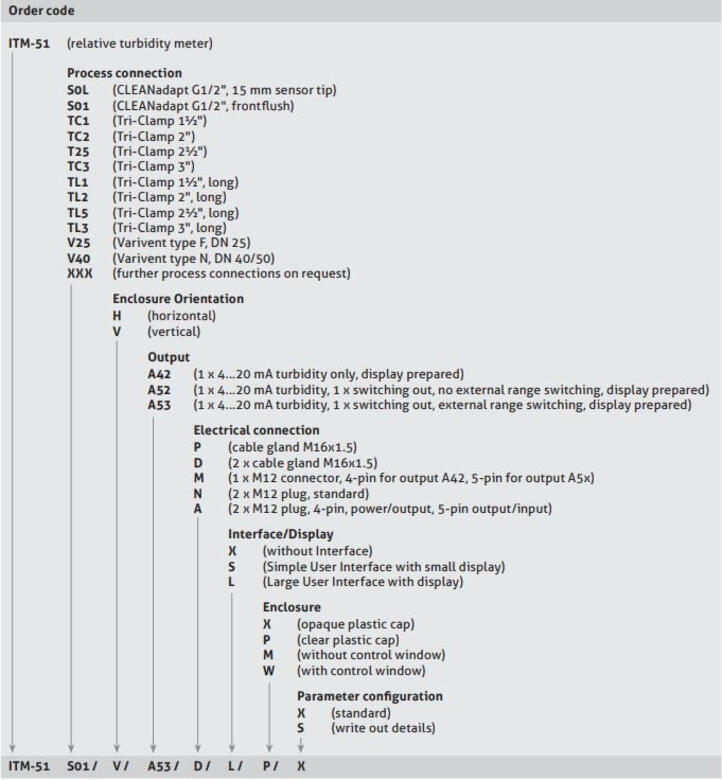

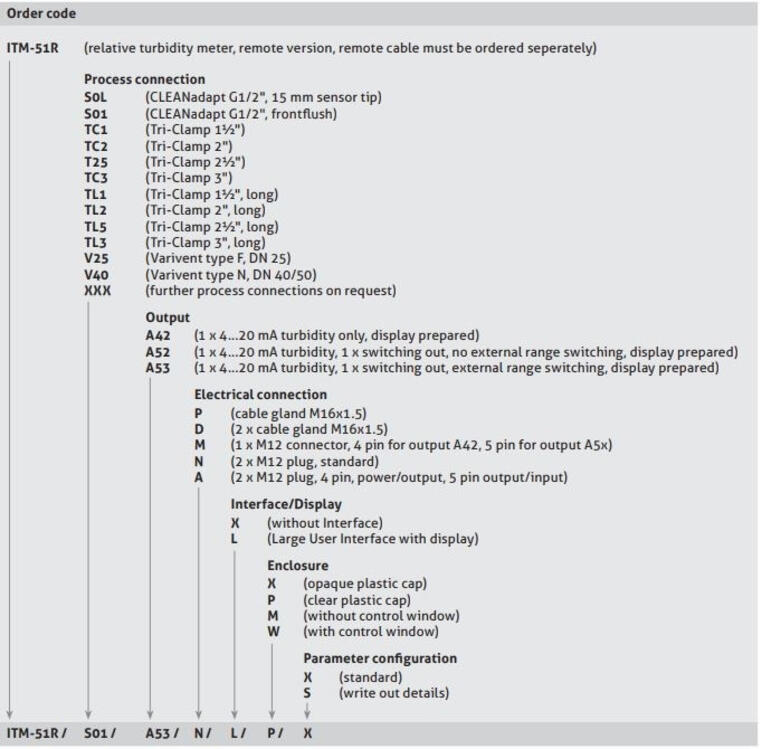

Please refer to the images below for ordering information.

OEM Automatics water and wastewater application specialists have gathered all our solutions in one place. Our products are used in everything from small municipal water works to larger regional plants.

Whether you’re pumping water, chocolate, oil or peanut butter knowing the product’s viscosity is essential to selecting the right pump. Find out more about viscosity and which pump may be suitable for your application!

Whether you're looking to upgrade your current solution or secure a more robust float switch for your next project, Taurus delivers performance you can count on.

When choosing between a pressure switch and a pressure sensor, the key lies in understanding your application. Our Pressure Monitoring experts breaks down the two devices for you.

Pumps are now officially part of our product offering! As we build our pump portfolio, we’re proud to announce that we are an official distributor of SAMOA Industrial, a well-established name in the fluid handling industry.

OEM Automatic's barcode scanner experts have broken down barcode technology to help you choose the right scanner for your application!

|

|

|

|

|

|

||

|---|---|---|---|---|---|---|

|

|

|

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

| Parts | Cable | Connection | Measurement accuracy | Price | ||

|---|---|---|---|---|---|---|

|

Art:

ITM-51

Copied

|

|

|

+/-3% - 0-999NTU ; +/- 5% > 999NTU

|

| ||

Art:

ITM-51R

Copied

|

standard 5,10,25m

|

M12

|

+/-3% - 0-999NTU ; +/-5% > 999NTU

|

|

Select a variant in the list