CROUZET MOTORS

Crouzet - BLDC worm geared motor with integrated TNi21 drive

The TNi21 integrated drive is ideal for applications where speed and torque control is required.

The long lifetime of the brushless motor (>20,000 hours with rated load) means it is ideal for continuous or long duty applications.

Having the drive integrated into the motor can also save control panel space, reduce cabling and save set-up time.

3 motor sizes available with the same diameter (57mm x 57mm), with increasing motor lengths for more power/torque.

Planetary & worm gearbox options available for reducing the speed & increasing the output torque.

Pre-set I/O mean that the motor can be used immediately without any complex preliminary set-up. It can be controlled via basic switches or by external PLC.

Motor power and logic connections are via cable output or connector options.

The motors are rated to IP65 dust/water protection class as standard.

Options for adapation to the standard motor include adding an encoder, holding brake, special output shaft, special connectors, upgraded IP protection & special firmware developed according to your specific application requirements.

* Product datasheets & 3D drawing for 0-10Vdc, cable version attached as an example. Further information for PWM version, brake options & connector version available upon request.

Full documentation & user manuals also available upon request.

- 12→32 V dc, 77→133 W, 65→800 rpm, 10 Nm max

- Speed & torque control. Easy use

- Reduce control panel space & cabling

- Long life (>20,000 hours)

- IP65 as standard

Selected variant

Technical data

| Integrated control | TNi21 |

|---|---|

| IP class | IP65 |

| Length | 163 mm |

| Life span | 20,000h |

| Max. torque | 10 |

| Number of pulses per revolution | 12 |

| Positioning feedback | Yes |

| Power | 77 W |

| Ratio | i=5→50:1 |

|---|---|

| Shaft diameter | 10 mm |

| Speed options | 80rpm→800rpm |

| Supply voltage | 12 V DC, 24 V DC |

| Type of gearbox | Worm |

| Weight | 1.65 kg |

Product description

The TNi21 integrated drive is ideal for applications where speed and torque control is required.

The long lifetime of the brushless motor (>20,000 hours with rated load) means it is ideal for continuous or long duty applications.

Having the drive integrated into the motor can also save control panel space, reduce cabling and save set-up time.

3 motor sizes available with the same diameter (57mm x 57mm), with increasing motor lengths for more power/torque.

Planetary & worm gearbox options available for reducing the speed & increasing the output torque.

Pre-set I/O mean that the motor can be used immediately without any complex preliminary set-up. It can be controlled via basic switches or by external PLC.

Motor power and logic connections are via cable output or connector options.

The motors are rated to IP65 dust/water protection class as standard.

Options for adapation to the standard motor include adding an encoder, holding brake, special output shaft, special connectors, upgraded IP protection & special firmware developed according to your specific application requirements.

* Product datasheets & 3D drawing for 0-10Vdc, cable version attached as an example. Further information for PWM version, brake options & connector version available upon request.

Full documentation & user manuals also available upon request.

Related

Synchronous Motors

Do you have a light duty motor requirement requiring a very stable output rpm ? If so, Crouzet synchronous motors are could well provide you ideal solution…

Recap of IATECH

Did you get a chance to visit IATECH at The Leicester Marriott Hotel? We had over 33 exhibitors and 8 fantastic Tech Talks throughout the day, Read all about the day, here.

OEM introduces IATECH - The Industrial Automation Technology Expo

We are thrilled to announce the launch of IATECH, THe Industrial Automation Technology expo at Leicester Marriott Hotel on 23rd October. The ultimate platform for showcasing our extensive product range and broad business areas, featuring over 50 leading suppliers under one roof!

Automation Components for Specialist Vehicles

The specialist vehicle industry can include automotive and EV, heavy vehicles such as agriculture and rail, and marine. This email takes you through some of the various products we offer for specialist vehicle applications.

Wheel motor drives for AGVs

AGV drive wheel motors cover a wide range of options – from a miniature unit on a small 20kg robot, tasked to move on a perfectly level and smooth indoor surface, up to passenger vehicle-sized robots working outside over fields and varying terrain.

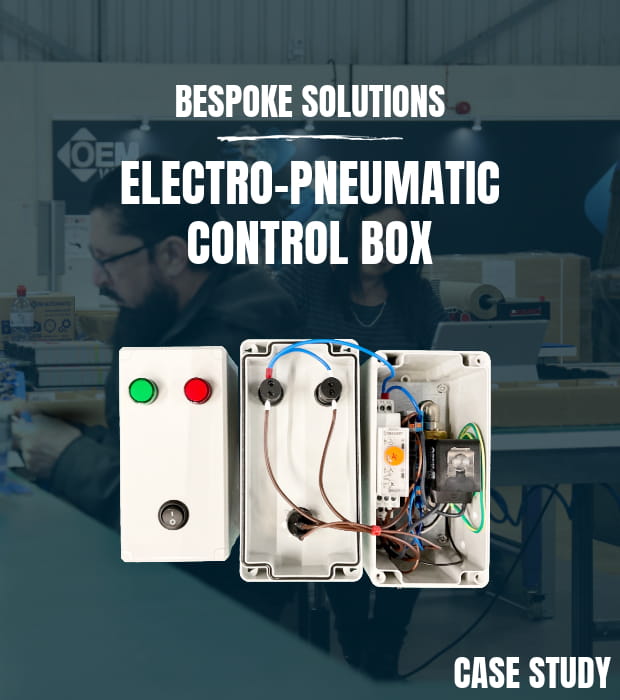

Case Study - Electro Pneumatic Control Box

At OEM Automatic, we can supply a series of components for your one project. All under one roof. This case study discusses how we supplied several components for our customer's new electro-pneumatic control box.