CROUZET CONTROL

Level control Relays HNM, HNE

The control relays HNM and HNE are used for level control.

HNM: Used for conducting liquids. Measures levels with resistive sensors. The principle is based on measurement of the apparent resistance between two recessed electrodes. When this value is less than the limit value indicated at the front, the relay output changes over. To avoid electrolysing, AC is applied to the electrodes.

HNE: *Now obsolete* Controls the levels of non-conducting and conducting materials using input/output sensors (NPN, PNP) that detect high or low level. Green LED indicates supply voltage and yellow LED indicates active relay output. If the LEDs flash, this indicates incorrect setting.

A rotary switch on the front is used for selecting the measurement range and filling/emptying function. With another switch, the number of levels can be set (1 or 2) and the type of delay if the function position for 1 level has been selected. The positions of these switches are registered when the operating voltage is switched on. If the switch is in the wrong position, the relay will remain deactivated and the LEDs will flash to indicate incorrect setting. If the switch position is changed during operation, all LEDs begin to flash but the unit will continue to function normally with the function that was set at the most recent power connection. The LEDs return to normal function when the switch has been returned to its original position, which was set before the first power connection. Green LED (Un) indicates supply voltage OK. Yellow LED (R) indicates active relay output.

- Control of one or two levels

- Filling/emptying function

- HNM resistive sensor

- HNE digital sensor * obsolete

Selected variant

Technical data

| Approvals | CE, CSA, RoHS, UL |

|---|---|

| Breaking capacity | 5A, 250V AC/DC |

| Function | Level Control |

| Input | Resistive Probe |

| IP class connection | IP20 |

| IP class housing | IP30 |

| Mounting | 35 mm DIN-Rail |

| Output | Relay 2 pole C/O |

| Power consumption | 5 VA / 1.5 W |

| Sensor cable length max | 100 m |

| Storage temperature max | 70 °C |

|---|---|

| Storage temperature min | -40 °C |

| Supply voltage | 24-240V AC |

| Temperature operational max | 50 °C |

| Temperature operational min | -20 °C |

| Time delay startup | 0.6 s |

| Time delay when exceeding the limit value | 0,1-5s |

| Weight | 115 g |

Downloads

Technical illustrations

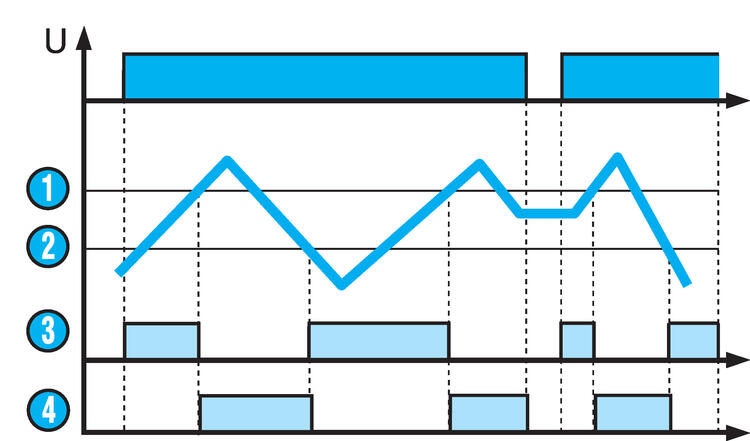

HNM-HNE emptying/filling, 2 levels

1: Highest level

2: Lowest level

3: Output relay R filling “Up”

4: Output relay R emptying “Down

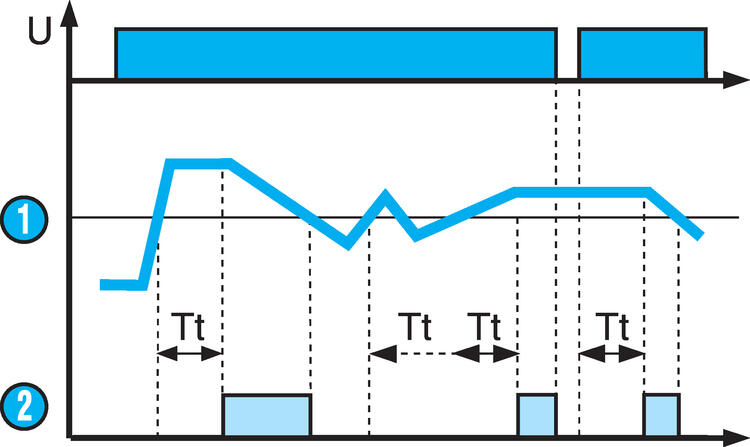

HNM-HNE emptying with one level activation delayed

1: Lowest sensor level

2: Output relay R

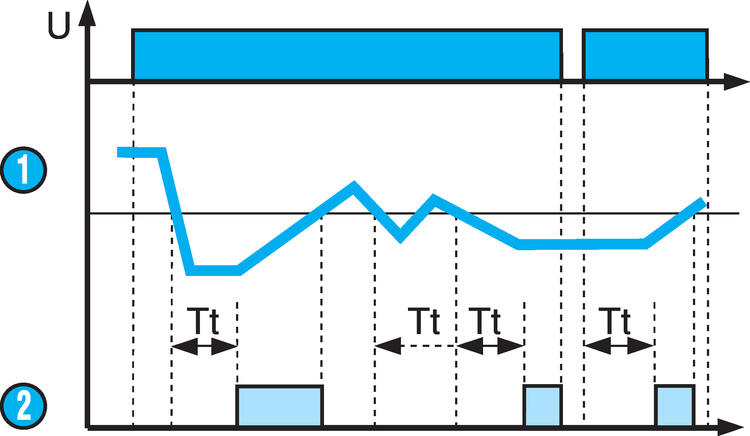

HNM-HNE filling with one level activation delayed

1: Level

2: Output relay R

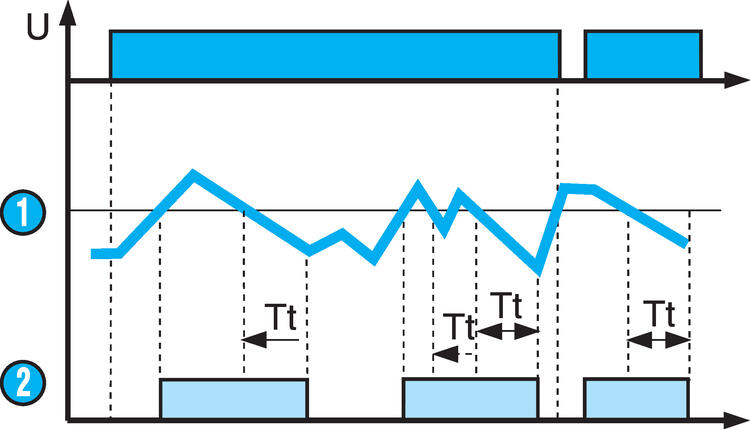

HNM-HNE emptying with one level deactivation delayed

1: Lowest sensor level

2: Output relay R

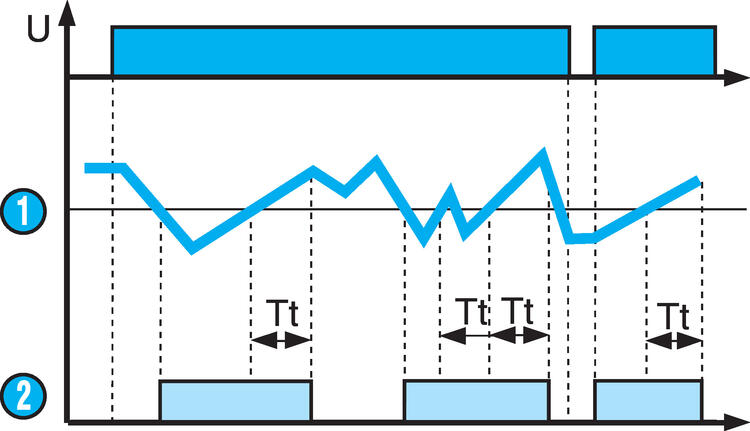

HNM-HNE filling with one level deactivation delayed

1: Lowest sensor level

2: Output relay R

Product description

The control relays HNM and HNE are used for level control.

HNM: Used for conducting liquids. Measures levels with resistive sensors. The principle is based on measurement of the apparent resistance between two recessed electrodes. When this value is less than the limit value indicated at the front, the relay output changes over. To avoid electrolysing, AC is applied to the electrodes.

HNE: *Now obsolete* Controls the levels of non-conducting and conducting materials using input/output sensors (NPN, PNP) that detect high or low level. Green LED indicates supply voltage and yellow LED indicates active relay output. If the LEDs flash, this indicates incorrect setting.

A rotary switch on the front is used for selecting the measurement range and filling/emptying function. With another switch, the number of levels can be set (1 or 2) and the type of delay if the function position for 1 level has been selected. The positions of these switches are registered when the operating voltage is switched on. If the switch is in the wrong position, the relay will remain deactivated and the LEDs will flash to indicate incorrect setting. If the switch position is changed during operation, all LEDs begin to flash but the unit will continue to function normally with the function that was set at the most recent power connection. The LEDs return to normal function when the switch has been returned to its original position, which was set before the first power connection. Green LED (Un) indicates supply voltage OK. Yellow LED (R) indicates active relay output.

Related

We now offer cable

What tri-rated cable are you currently using? Does the product or service you receive leave you wanting more? It’s time to ask the question. Because now, you’ve got options.

Terminal Blocks For Push In Connection Systems

This innovative push-in connection system enables time savings of up to 50%, whether you're wiring control panels or managing complex installations

Electrical Protection in the Solar Era: How to Choose Fuses for Modern Photovoltaic Installations

Solar energy has become a pillar of the global energy transition. The experts at OEM Automatic have broken down the role of photovoltaic fuses and their contribution to solar systems, as well as, how to choose the right solution for you.

Fuse links for semiconductor protection

Ultra fast-acting fuse links engineered specifically to shield delicate semiconductor devices.

Lightning and surge protection for DC and control signals

Do you need reliable protection for measuring and control equipment? DEHN YellowLine delivers voltage surge protection tailored for building, measuring, and control systems

MCBs vs ECBs: Which is best for securing DC circuits?

Choosing the right circuit breaker is important for protecting DC circuits. Two primary forms of protection are MCBs and ECBs. The experts at OEM Automatic breakdown the two circuit breakers for you!