ELECTROMEN

Electromen - EM-339-PLI

Parallel drive for 2 x DC motors 12-24 V dc, 2x10A

The EM-339-PLI drive has been designed for driving two 12-24Vdc actuators or motors in parallel synchronisation.

The synchronisation is achieved by comparing 2-channel quadrature pulse feedback (max freq input 700Hz per channel) from each motor. The drive will compensate small differences by adjusting the motor speeds & if synchronisation can still not be achieved the drive will stop the motors to avoid any potential mechanical problems. The homing routine function is to reset/balance pulse counts.

In a compact 78 x 73 x 25mm package, the drive can provide up to 2 x 10A continuous current (@ 2KHz PWM freq setting). Din rail kits are available for mounting inside a control panel.

With up to 24 settable parameters via the EM-236 plug in module or EM-268 USB connection with Ementool PC software, it is a fully programmable cost effective solution for many applications. For volume projects a fully factory customised solution can be provide to suit customer specific requirements.

|

Key features

• Four quadrant – Speed, direction, acceleration/deceleration and braking control

• End of travel limits – Pulse counting or limit switch input

• Current and temperature limiting – For protection against overload

• Auto-reverse – Anti-trap safety function upon current limit activation

• Brake output – 2A output for releasing magnetic brakes

• Fault output & on board LED – To identify fault conditions

- 12-24Vdc, 2x10A continuous, 2x20A 25% duty

- Synchronized parallel driving

- Operates with pulse feedback from motors

- Homing cycle & end of travel limits set by pulse counting

- Programmable with wide range of motor control functions

Selected variant

Technical data

| Analogue input | 0-5V, 0-10V or 4...20mA |

|---|---|

| Control type | Speed, Braking, Direction, Torque, Position, Soft start / stop |

| Current setting range | 1-25 A |

| Dimensions length x width x height | 78x73x25mm |

| Logic input high | >4V = ON |

| Logic input low | <1V = OFF |

| Max continuous current | 2x10 A |

| Mounting | DIN rail |

| Operating temperature | -20°C...+60°C |

|---|---|

| Peak current | 2x20 |

| PWM frequency | 2kHz/16kHz |

| Suitable engine | DC |

| Supplier | Electromen |

| Supply voltage | 12 V DC, 24 V DC |

| Weight | 110 g |

Product description

The EM-339-PLI drive has been designed for driving two 12-24Vdc actuators or motors in parallel synchronisation.

The synchronisation is achieved by comparing 2-channel quadrature pulse feedback (max freq input 700Hz per channel) from each motor. The drive will compensate small differences by adjusting the motor speeds & if synchronisation can still not be achieved the drive will stop the motors to avoid any potential mechanical problems. The homing routine function is to reset/balance pulse counts.

In a compact 78 x 73 x 25mm package, the drive can provide up to 2 x 10A continuous current (@ 2KHz PWM freq setting). Din rail kits are available for mounting inside a control panel.

With up to 24 settable parameters via the EM-236 plug in module or EM-268 USB connection with Ementool PC software, it is a fully programmable cost effective solution for many applications. For volume projects a fully factory customised solution can be provide to suit customer specific requirements.

|

Key features

• Four quadrant – Speed, direction, acceleration/deceleration and braking control

• End of travel limits – Pulse counting or limit switch input

• Current and temperature limiting – For protection against overload

• Auto-reverse – Anti-trap safety function upon current limit activation

• Brake output – 2A output for releasing magnetic brakes

• Fault output & on board LED – To identify fault conditions

Related

Synchronous Motors

Do you have a light duty motor requirement requiring a very stable output rpm ? If so, Crouzet synchronous motors are could well provide you ideal solution…

Recap of IATECH

Did you get a chance to visit IATECH at The Leicester Marriott Hotel? We had over 33 exhibitors and 8 fantastic Tech Talks throughout the day, Read all about the day, here.

OEM introduces IATECH - The Industrial Automation Technology Expo

We are thrilled to announce the launch of IATECH, THe Industrial Automation Technology expo at Leicester Marriott Hotel on 23rd October. The ultimate platform for showcasing our extensive product range and broad business areas, featuring over 50 leading suppliers under one roof!

Automation Components for Specialist Vehicles

The specialist vehicle industry can include automotive and EV, heavy vehicles such as agriculture and rail, and marine. This email takes you through some of the various products we offer for specialist vehicle applications.

Wheel motor drives for AGVs

AGV drive wheel motors cover a wide range of options – from a miniature unit on a small 20kg robot, tasked to move on a perfectly level and smooth indoor surface, up to passenger vehicle-sized robots working outside over fields and varying terrain.

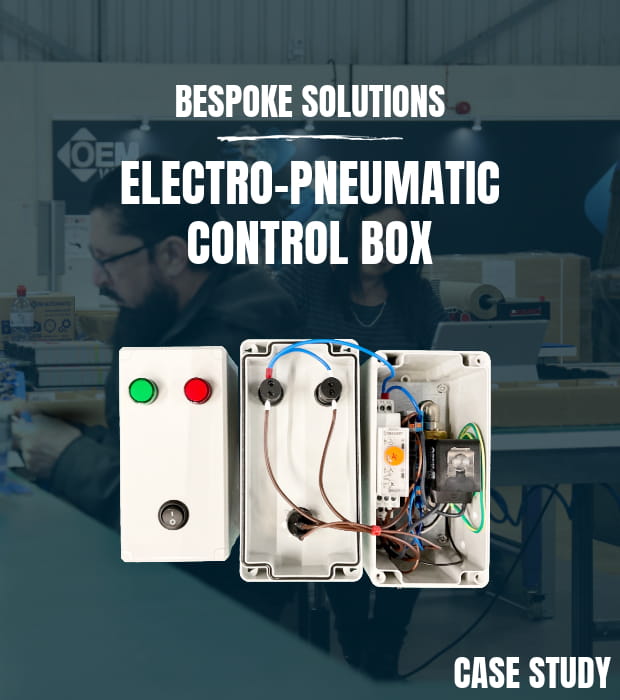

Case Study - Electro Pneumatic Control Box

At OEM Automatic, we can supply a series of components for your one project. All under one roof. This case study discusses how we supplied several components for our customer's new electro-pneumatic control box.