The Push In Technology You Need at OEM Automatic

In today's fast-paced environment, efficiency and reliability are two crucial factors in the industrial sector. The need for streamlined processes, reduced installation times, and dependable connections has led to the adoption of push-in technology, which has gained popularity in the last 20-30 years and used as an alternative to screw-in products.

OEM Automatic has integrated push-in technology into it's product offering for many years now. In this blog post, we'll explore the various benefits of push-in technology and some of the products we offer that make use of this innovation, such as push-in terminals, push-in sockets, and even push-in heaters.

Push in Technology

Push in technology is revolutionising the way we connect wires and components in the industrial and manufacturing sectors. It eliminates the need for traditional screw terminals and offers several advantages that save time, reduce complexity, and enhance reliability.

Here are some advantages of push in technology below:

Quick and Easy Installation

One of the advantages of push in technology is the speed of installation. With no screws or tools required, connecting wires becomes a breeze.

This streamlined process can save up to 50% of your installation time, allowing you to complete projects more efficiently.

Simplicity and Safety

Push in products are designed with simplicity in mind. Even without extensive technical knowledge, anyone can use them. This ease of use not only simplifies the installation process but also makes maintenance and replacement tasks more straightforward.

Space-Saving Designs

Push in products enable more compact designs, particularly valuable in applications where space is limited. This space-saving capability can lead to the development of smaller, more efficient products.

Reliability and Vibration Resistance

In an industrial environment, reliability is paramount. Push in products provide a secure and vibration-resistant connection, ensuring that your systems operate consistently and without disruptions.

BlogPush-in Products at OEM Automatic

Now that we've highlighted the benefits of push-in technology, let's take a closer look at some of the outstanding push-in products available at OEM Automatic:

Push In Signal Converters and Loccbox

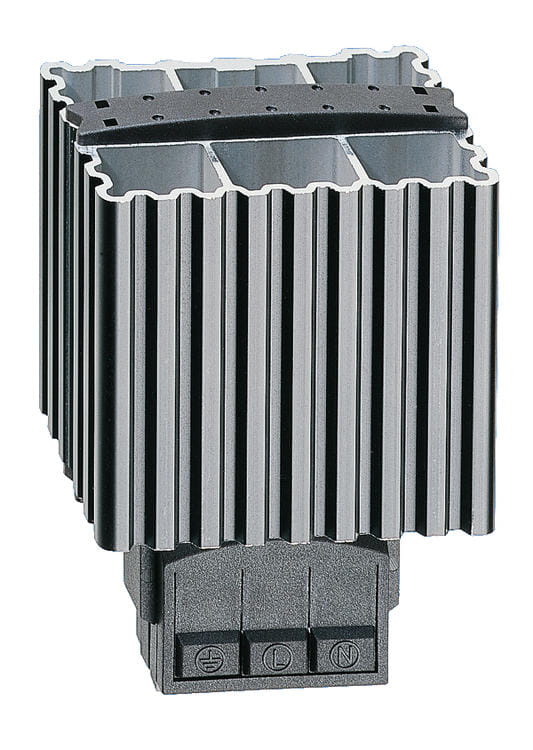

Push In Thermostats and heaters

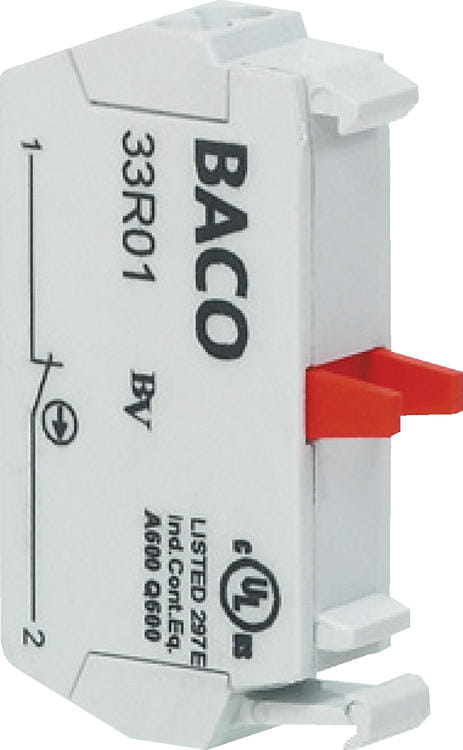

Push-in Contact Blocks

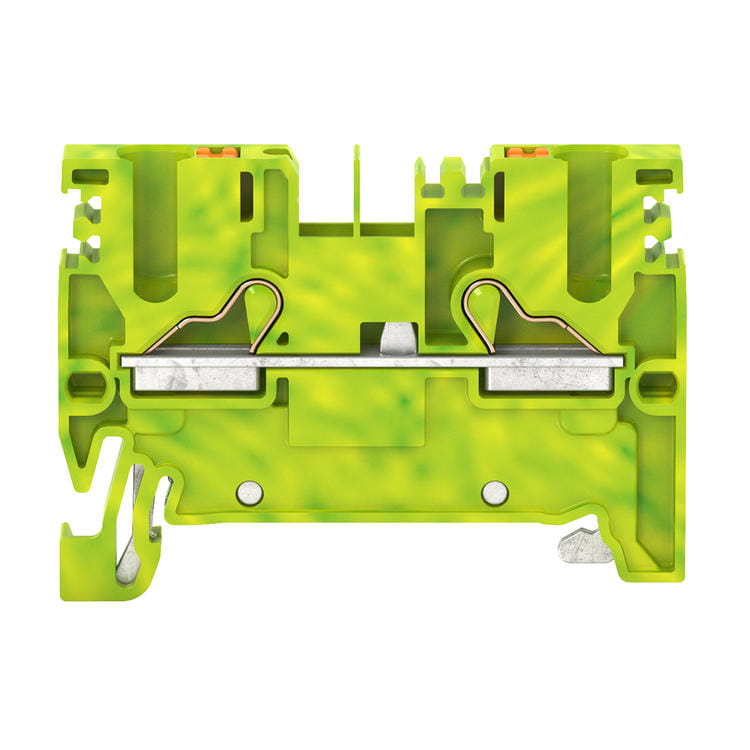

Push In Terminals

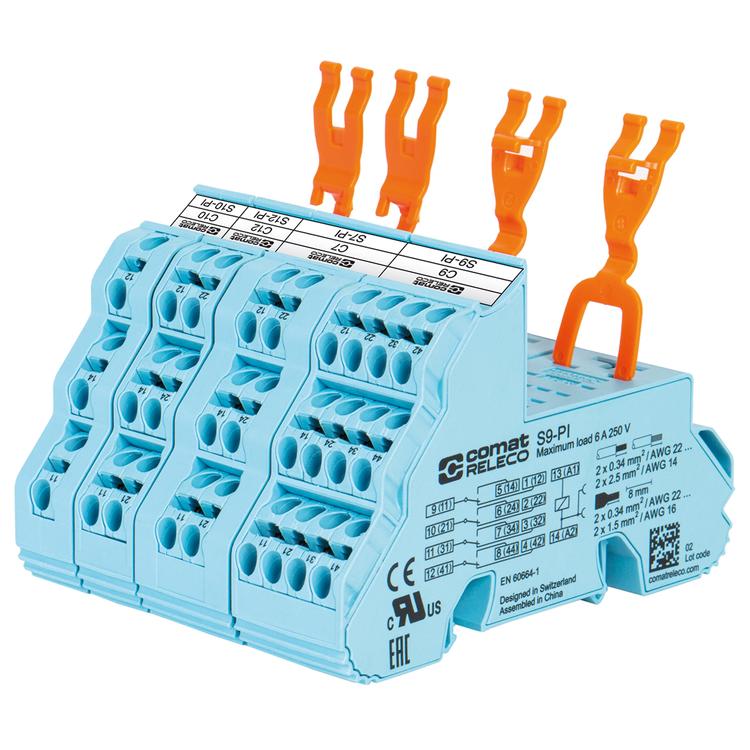

Push In sockets

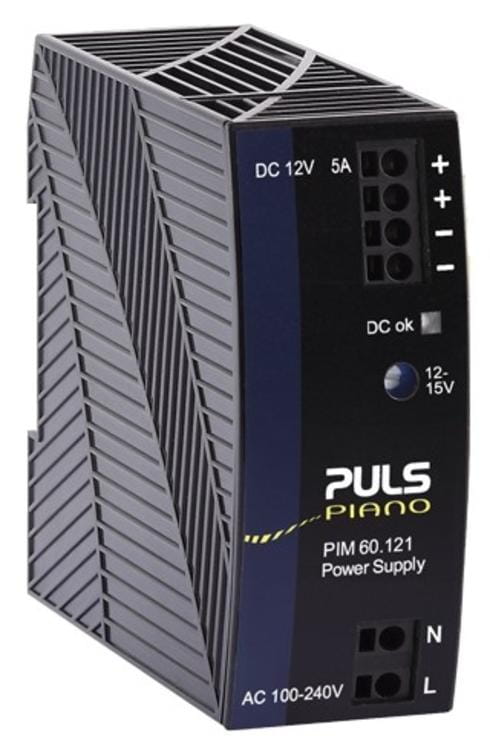

Push In Power Supplies

Why you may choose push-in over screw terminals

While traditional screw terminals serve their purpose, push-in technology can overcome some of its challenges.

Torque Sensitivity: Screw terminals require the correct torque to be applied. Over-tightening can damage wire copper, while under-tightening can lead to loose connections. Push in terminals eliminate this concern.

Maintenance Challenges: Products with screw terminals can be more difficult and time-consuming to install, maintain and replace. Push-in technology simplifies these processes, saving both time and effort.

Push-in technology is a game changer in the industrial sector, offering significant advantages in terms of installation speed, simplicity, space-saving designs, and reliability.

OEM Automatic is committed to providing solutions that improve efficiency and reduce downtime. Explore our range of push-in products and experience the future of industrial connectivity today.

Speak to us about your requirements by emailing [email protected] or calling 0116 284 9900.