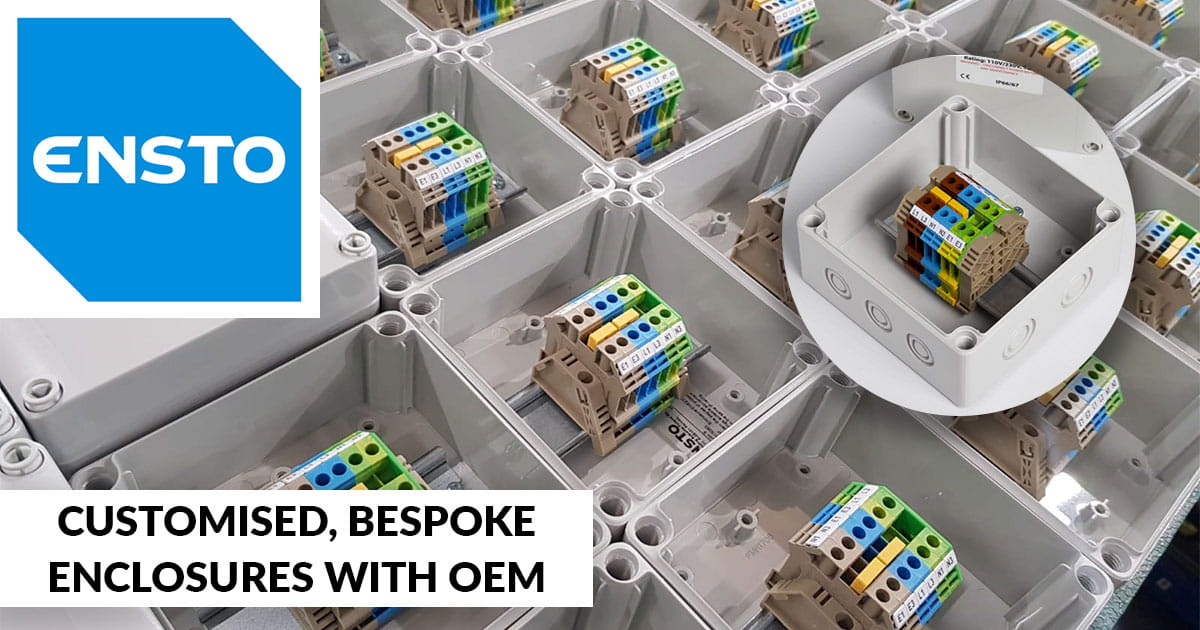

Get customised, bespoke enclosures with OEM

Having a protective house for your components is crucial in any electrical environment, which is why enclosures are one of our main offerings, they protect from the outside and keep components all in one place!

Enclosures may need to look a little appealing, or suit the environment they are in. Which is why OEM and Ensto create customised enclosures for our customers…

Examples of industries that require a customised enclosure

- EV charging stations

- Food and beverage

- Trace heating

- Agriculture

- Crane & equipment

Why would you need a customised enclosure?

- A high-quality, robust enclosure can improve the aesthetics of the application

- Identification purposes

- Branding

- Fit to your bespoke electrical requirements e.g., din rail assembly

- Original Ensto enclosure design may not be suitable for you

First, choose the right enclosure for you

Consider these following elements when choosing an enclosure:

Material

Choose from thermoplastics, polyester, or aluminium. Which one will ensure safety of equipment? However, if you require a certain material, Ensto can work with you on material selection.

Dimensions

What is the maximum and minimum dimensions of your application? Will you add further components? Again, we can create customer specific sizes.

What protection is required?

Ensto IP codes range between IP55 and IP67 and even IP69K if required. For example, if the enclosure needs to be dust tight and able to withstand high pressure and steam.

Ensto enclosures also include IK code and UL, for example the American market may requires UL listed enclosures.

Flammability

Does the enclosure need to be highly flammable? That depends on your application.

Our polycarbonate enclosures are flammable tested according to UL 746C.

Plastic enclosures also fulfil the glow wire test according to IEC 60695-2-11

Certification

Ensto Cubo enclosures are certified in accordance with EN 62208 (SGS Fimko). Most of our polycarbonate enclosures are also UL and cUL listed.

Customisation with Ensto

OEM Automatic work with Ensto to supply bespoke, tailored enclosures to your exact specification. We can work with you on the size, material, colour, type, and branding of the enclosure.

This can include anything from hole cut-outs, silk screening, custom plastic colours and fully populated systems.

We also give technical and application advice on these enclosures.

BlogCustomisation with OEM’s technical workshop

OEM can also offer integration services of third-party components with the help of our in-house technical workshop.

This service includes custom built DIN rail assemblies, profiled enclosures, and kitted parts through our well-equipped technical workshop to optimise your build time and reduce stock holding.

You can read about our added value service here.

The steps that OEM take to create a customised enclosure for you

- Initial conversation with OEM outlining requirements and quantities

- Customer sends over 3D drawings of the specific enclosure required for application

- OEM delivers pricing, structured around quantities

- We send you samples if needed

- Enclosures are manufactured by Ensto and sent directly to you

You may require a customised enclosure, or Ensto’s standard enclosures which you can find here.

Whatever the requirement, you can contact us by emailing [email protected] or calling 0116 284 9900