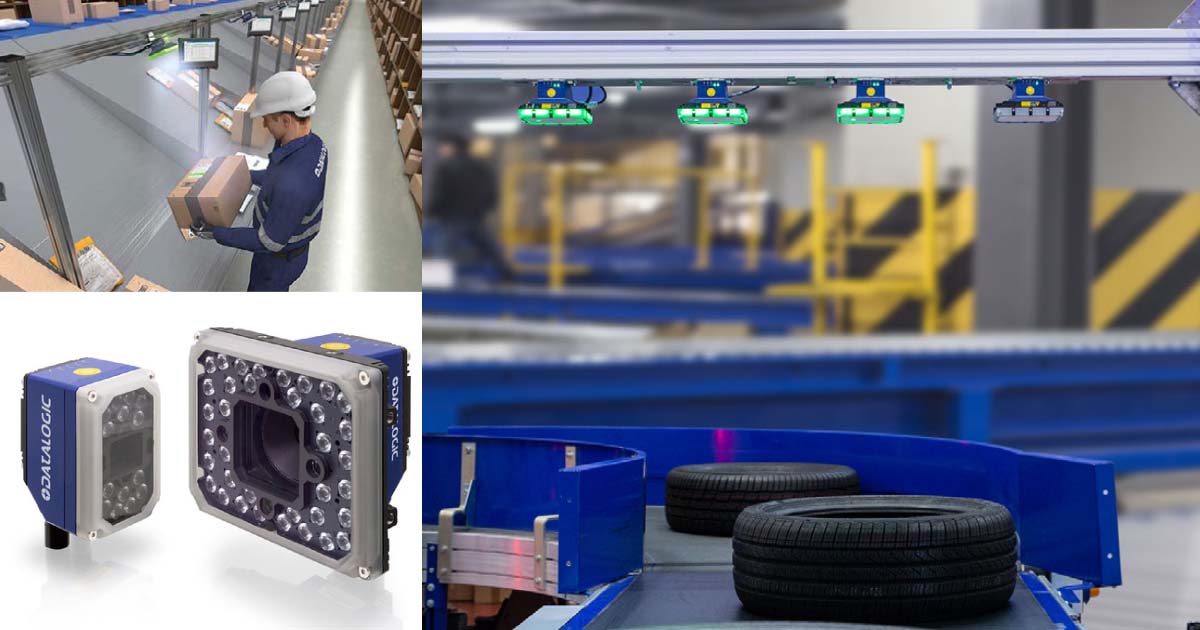

There’s a new member of Datalogic’s Matrix family of industrial imagers – Matrix 320. Datalogic has brought its expertise in traceability to bear once again, and Matrix 320 is its most advanced image-based barcode reader.

Reassuringly, it has all the familiar features of the Matrix family. There’s easy setup with continual feedback, an extensive range of modular lens and lighting options, and cross-network industrial connectivity for any situation.

The Matrix 320 is extremely versatile with a field of view unrivalled in its category. It brings industry-leading performance, flexibility, and a low total cost of ownership to machine builders and end users. It effortlessly reads the most challenging of printed labels and directly marked parts.

By utilising the latest in sensor technology, the Matrix 320 provides the most cost-effective solution available on the market. In addition, it can be used in a fixed position, replacing the need for operators to scan items manually using handheld barcode scanners.

It can transform traceability capabilities in all logistics, intralogistics and shop-floor applications.

When traceability is improved, then performance is improved. When performance is improved, then productivity is improved.

‘Empower your traceability, boost your productivity,’ as Datalogic says.

Product newsThe large field of view and amazing depth of field combine to provide the capability to meet the highest speed demands in the packaging industry.

The Matrix 320’s state-of-the-art 16:9 CMOS 2MP sensor gives an unbelievable 3MP performance. There’s an optimum balance of cost and performance, with no uncovered areas and no wasted pixels.

The advanced image processing electronics and smart lighting solutions provide a 60 fps high-speed imager that can easily decipher the most challenging and hard-to-read barcodes (as in intralogistics) or DPM barcodes (as in the automotive and electronics industries). The Matrix 320 performs flawlessly, even with challenging combinations of printed and DPM codes on the same surface.

The Matrix 320 reader is flexible. It has unlimited configurations to solve the most challenging applications.

A ready assembled, fully functional Matrix 320 for use straight out of the box is available. Or your exact needs can be met with a model customised from the wide range of lenses, lighting, filters, covers and accessories.

Lighting options are smart and configurable. Colour and intensity are easily selectable based on the code type, material the code is on, and the material’s colour. High power and very high power lighting options provide a flexible application fit.

Liquid lens (LQL) and C-MOUNT permit extremely flexible reading.

The imager is modular and can be easily adapted to most vertical applications.

It is simple to remotely change focus between batches in a live production environment without needing to open or touch the device.

Remote focus on LQL lends itself well to situations requiring multiple images of the same object at different focal distances.

Last, but no means least in these challenging times, the Matrix 320 meets hygiene and safety requirements in the workplace.

It can be fixed to read fast-moving barcodes in a variety of industries and applications, meaning that operators do not need to maintain scanner cleanliness as they would with hand-held scanners. This allows them to concentrate on other activities, leading to greater line efficiencies.

The simple aiming system with cross projection and highly visible read feedback on the label provides easy-to see visual confirmation.

Contact our Machine Vision and Code Reading team for more information: [email protected], alternatively see more information about the product using the link below.