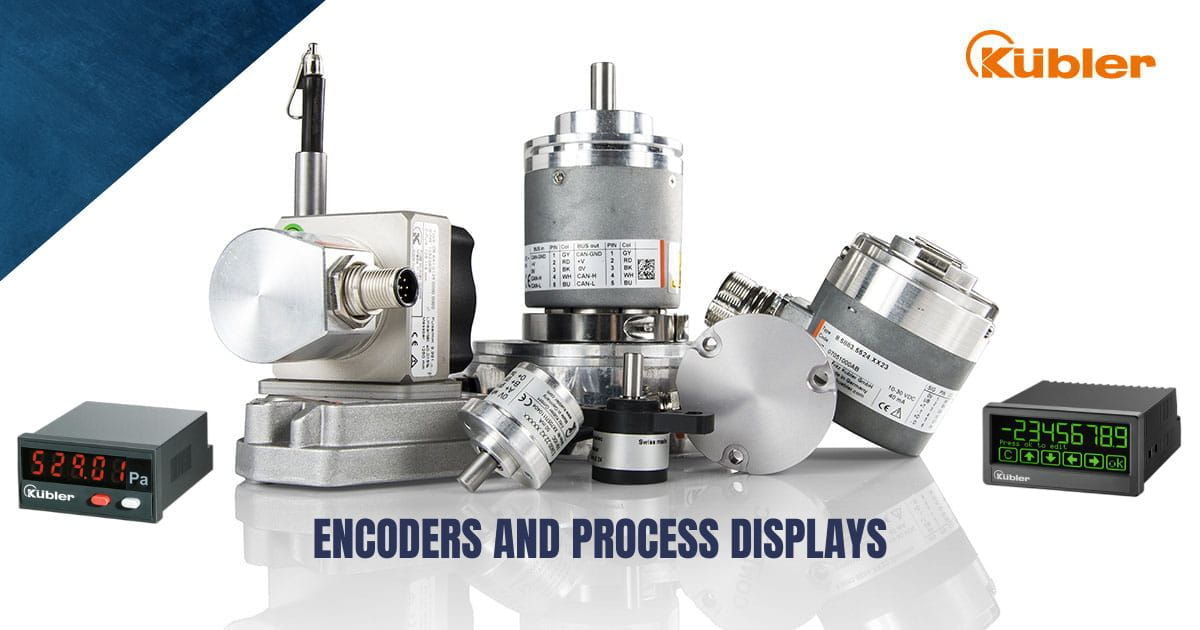

Combine Encoders and Process Displays with Kubler

Unlock Efficiency and Precision with Kubler Encoders and Process Displays

In various industrial and scientific applications visualising movement and rotation can be crucial. We present Kublers ultimate package: Encoders and Process Displays which can be used together to create efficient processes.

Scroll down to learn more…

About Kubler Encoders and Process Displays

What Are Encoders?

An encoder is used to measure speed, position or movement. In our range, we offer stepped encoders that give one pulse number per revolution, as well as absolute encoders that have an absolute position.

Absolute encoders can be either single-turn or multi-turn.

A single-turn encoder is well suited to the use of short motion control applications where position verification is required within a single oscillation of the encoding shaft.

A multi-turn encoder is better for applications that involve complex or long positioning requirements.

For the harshest environments, we also offer non-contact/non-contact angle sensors that are insensitive to oil, water, dust, peeling, high IP class and completely free of mechanical parts.

What Are Process Displays?

Process displays are an instrument that use pulses from an encoder to display variables such as: rotation, distance speed and flowrate.

Process displays offer operators and engineers with a comprehensive and intuitive interface to track and display key parameters such as position, speed, and rotational direction, facilitating efficient process control and optimization.

Kubler process displays are widely used in a diverse range of fields including automation, robotics, machine tools, and motion control systems.

Using Encoders And Process Displays Together

When paired with encoders, Kubler process displays enable operators and engineers to have a clear and immediate understanding of the rotational motion within a system. They provide visual feedback that allows for quick decision-making, troubleshooting, and adjustment of process variables.

Examples of Encoders and Process Displays Used Together

Material Handling / Conveyors

Encoders can be integrated into the conveyor system to accurately measure the position and speed of the moving belts or rollers. The encoder generates precise feedback regarding the conveyor's movement, which is then displayed on a screen or control panel. Operators can monitor the conveyor's speed, direction, and position in real-time, allowing them to make necessary adjustments to ensure smooth material flow and prevent bottlenecks.

Lift Industry – Draw Wire Encoders

Encoders can be integrated into the lift's motor or traction system to provide precise position feedback. The encoder tracks the movement of the lift car and accurately determines its location within the building. This information is then displayed on a panel inside the lift, showing the current floor level to passengers. The floor level display allows passengers to easily identify their desired floor and ensures accurate alignment with the landing doors.

Cranes - Inclinometers and Draw Wire Encoders

Inclinometers can be used to measure the angle and extension of the crane's boom. By attaching an encoder to the boom mechanism, the system can accurately track the boom's movement and position. The encoder's feedback is displayed on the screen or control panel, providing operators with real-time information on the boom angle and extension. This enables precise control over the reach and orientation of the crane, ensuring accurate load placement and avoiding potential hazards.

Solar - Inclinometer - Measures Angle of Solar Panel

Encoders can be integrated into sun tracking systems that adjust the position of solar panels to maximize sunlight exposure. This information can be displayed on a screen or control panel.

Wind

Encoders are essential in monitoring and controlling the rotor speed of wind turbines. By measuring the rotational speed of the turbine's main shaft, encoders provide real-time feedback on the turbine's rotation. This information is displayed on screens or control panels, allowing operators to monitor and adjust the rotor speed within safe and efficient operating limits.

Packaging Machines

Encoders can provide feedback on the position and alignment of products on the packaging line. By integrating encoders into the product handling mechanisms, such as conveyor systems. The encoder's feedback is displayed on screens or control panels, allowing operators to monitor the product alignment and adjust as necessary.

By using Kubler Encoders and Process Displays in conjunction, you can streamline your processes, improve efficiency, and achieve precise control over essential parameters. By seamlessly integrating these powerful solutions into your industrial operations, you can unlock new levels of productivity and accuracy.

You can purchase Encoders and Process Displays under one order to save on shipping costs and have a solution that works together.

To enquire about this Kubler Package, email [email protected] or call 0116 284 9900.

Blog