SENSECA

MULTISIGNAL FOR LCM SERIES

This universal signal processor was designed as interface for continuous level sensors with potentiometric output (LC series). Subsequently evolved until the current version that can be interfaced with any sensor or signal transmitter. This electronic unit handles standard industrial signals 0-5V, 0-10V, 0-20mA, 4-20mA, frequency and potentiometers. The instrument allows the simultaneous display in digital and analog format (bargraph) of the acquired signal. The measurement can be represented in percentage format, or in the more common engineering units. The linearization of the signal is provided, for example, in case of level measurements of cylindrical tanks arranged horizontally. Within the measuring range is possible to program up to six alarms thresholds with SPDT output relay. The programming is completely digital, with no adjustment trimmers, with saving the operating parameters on a non-volatile EEPROM type memory.

- LCD display with back light

- Input signals: (0)4-20mA , 0-5V, 0-10V, 500-20KΩ, 0,1-10000Hz

- Output signals: (0)4-20mA , 0-5V, 0-10V

- Up to 6 alarm thresholds with adjustable differential

Selected variant

Technical data

Downloads

Product description

This universal signal processor was designed as interface for continuous level sensors with potentiometric output (LC series). Subsequently evolved until the current version that can be interfaced with any sensor or signal transmitter. This electronic unit handles standard industrial signals 0-5V, 0-10V, 0-20mA, 4-20mA, frequency and potentiometers. The instrument allows the simultaneous display in digital and analog format (bargraph) of the acquired signal. The measurement can be represented in percentage format, or in the more common engineering units. The linearization of the signal is provided, for example, in case of level measurements of cylindrical tanks arranged horizontally. Within the measuring range is possible to program up to six alarms thresholds with SPDT output relay. The programming is completely digital, with no adjustment trimmers, with saving the operating parameters on a non-volatile EEPROM type memory.

Related

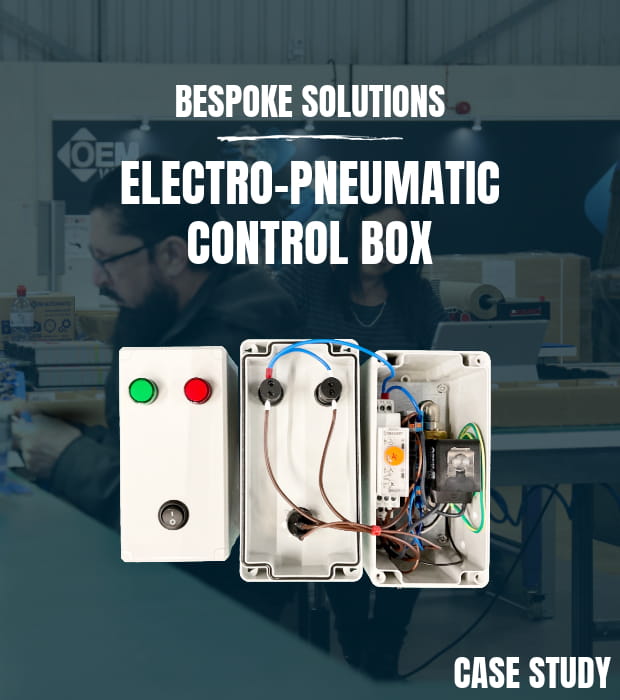

Case Study - Electro Pneumatic Control Box

At OEM Automatic, we can supply a series of components for your one project. All under one roof. This case study discusses how we supplied several components for our customer's new electro-pneumatic control box.

New Hydrogen Approved Pressure Switches

OEM is pleased to announce a range of hydrogen-approved mechanical pressure switches, by Suco! Today, hydrogen plays a key role in climate-neutral energy generation and storage.

Feel the force with Wika force measurement

OEM Automatic proudly welcomes the addition of WIKA to its lineup. Wika Force brings a new dimension to the realm of force measurement. The integration of WIKA into the OEM Automatic pressure and flow range represents a significant advancement in force measurement technology!

Georg Fischer New Process Automation Supplier

Georg Fischer is a globally renowned provider of process automation systems and solutions for various industries. Join us as we delve into the advantages and opportunities that this new addition brings to you.

ESI's hydrogen compatible pressure sensor range

Using hydrogen as a source of energy is an emerging market. ESI have a selected range of pressure sensors that are hydrogen-compatible.

Process and packaging automation components at OEM

Automated machinery in the process and packaging industries is constantly developing. Find out how we can help to automate process and packaging machinery at OEM.