APLISENS

Aplisens - SGE-25 Level Sensor

Hydrostatic

The SGE-25 hydrostatic level probe measures liquid levels, based on a simple relationship between the height of the liquid column and the resulting hydrostatic pressure. The pressure measurement is carried out on the level of the separating diaphragm of the immersed probe and is related to atmospheric pressure through a capillary in the cable. The active sensing element is a piezoresistant silicon sensor separated from the medium by an isolating diaphragm. The electronic amplifier, which works in combination with the sensor, and is meant to standardize the signal, is additionally equipped with an overvoltage protection circuit, which protects the probe from damage caused by induced interference from atmospheric discharges or from associated heavy current engineering appliances.

If there is a possibility of turbulence in the tank (for example, because of the mixer operating mixers or a turbulent inflow), the probe should be installed inside a screening tube (e.g. made of PVC). If the probe is to be lowered deeper than 100m, the cable should be hanged at steel lifting rope. Cleaning the probe diaphragm by mechanical means is strictly prohibited.

Options include Exia, DNV approval, cable options, output options and Pt100 sensor.

Applications include tanks, deep wells, waste water, oil/fuel etc

- 1..500mH2O range

- 4-20mA

- ATEX option

- Marine certification (DNV) option

Selected variant

Technical data

| Cable length | 10 m |

|---|---|

| Deviation max | 0,6 % |

| IP class | IP68 |

| Material | Stainless steel |

| Material cable | PUR |

| Material of body | Stainless steel 316L |

| Material of wetted parts | Hastelloy C, Stainless Steel SIS2350 (316L) |

| Measurement technology | Pressure |

| Mounting | Submersible |

| Pressure range max | 1 mH2O |

|---|---|

| Pressure range min | 0 mH2O |

| Signal type | 4-20 mA |

| Supply voltage dc max | 36 V DC |

| Supply voltage dc min | 8 V DC |

| Temperature of media from | -25 °C |

| Temperature of media to | 40 °C |

Product description

The SGE-25 hydrostatic level probe measures liquid levels, based on a simple relationship between the height of the liquid column and the resulting hydrostatic pressure. The pressure measurement is carried out on the level of the separating diaphragm of the immersed probe and is related to atmospheric pressure through a capillary in the cable. The active sensing element is a piezoresistant silicon sensor separated from the medium by an isolating diaphragm. The electronic amplifier, which works in combination with the sensor, and is meant to standardize the signal, is additionally equipped with an overvoltage protection circuit, which protects the probe from damage caused by induced interference from atmospheric discharges or from associated heavy current engineering appliances.

If there is a possibility of turbulence in the tank (for example, because of the mixer operating mixers or a turbulent inflow), the probe should be installed inside a screening tube (e.g. made of PVC). If the probe is to be lowered deeper than 100m, the cable should be hanged at steel lifting rope. Cleaning the probe diaphragm by mechanical means is strictly prohibited.

Options include Exia, DNV approval, cable options, output options and Pt100 sensor.

Applications include tanks, deep wells, waste water, oil/fuel etc

Related

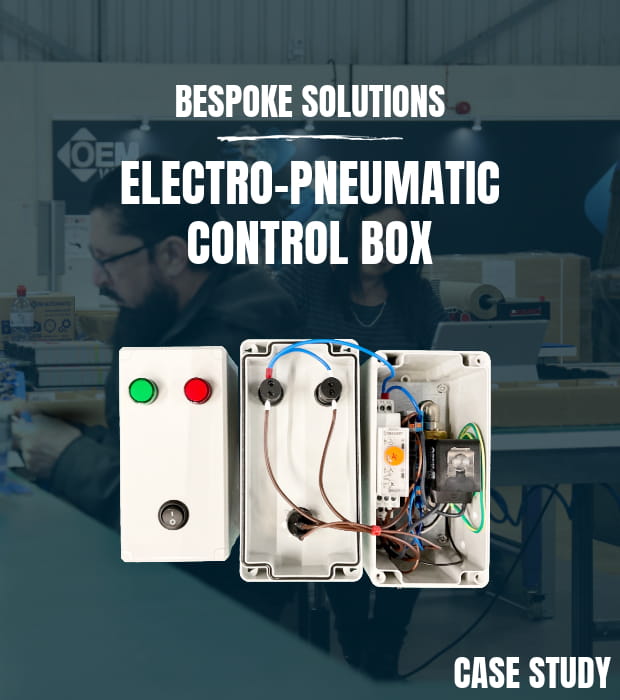

Case Study - Electro Pneumatic Control Box

At OEM Automatic, we can supply a series of components for your one project. All under one roof. This case study discusses how we supplied several components for our customer's new electro-pneumatic control box.

New Hydrogen Approved Pressure Switches

OEM is pleased to announce a range of hydrogen-approved mechanical pressure switches, by Suco! Today, hydrogen plays a key role in climate-neutral energy generation and storage.

Feel the force with Wika force measurement

OEM Automatic proudly welcomes the addition of WIKA to its lineup. Wika Force brings a new dimension to the realm of force measurement. The integration of WIKA into the OEM Automatic pressure and flow range represents a significant advancement in force measurement technology!

Georg Fischer New Process Automation Supplier

Georg Fischer is a globally renowned provider of process automation systems and solutions for various industries. Join us as we delve into the advantages and opportunities that this new addition brings to you.

ESI's hydrogen compatible pressure sensor range

Using hydrogen as a source of energy is an emerging market. ESI have a selected range of pressure sensors that are hydrogen-compatible.

Process and packaging automation components at OEM

Automated machinery in the process and packaging industries is constantly developing. Find out how we can help to automate process and packaging machinery at OEM.