SENSECA

Honsberg - FF Series Flow Switch

Piston

The Honsberg FF series flow switch is a simple unit which indicates when a specific flow rate has been acheieved. The basic operation of the switch is when the volume flow raises a piston (fitted with a magnet) out from a valve seat which is against a spring force and when the specificed flow rate is achieved the piston actuates an hermetically separated reed switch. The FF is designed for horizontal inwards flow; switching head not recommended underneath; other installation positions are possible; the installation position affects the switching point and range.

*The switch point must always be specified/factory-set item

- Adjusted switching value

- Highly reproducible

- Insensitive to dirt

- Adjustment for oil or gas

- Special values

- Switching Range 0,4..90 l/min H₂O

- Water (oils on request)

- G¼ up to G1½

- Bronze, brass, stainless steel, ferrite & NBR

- Pressue range from 16 bar up to 200 bar

Selected variant

Technical data

| Accuracy | ± 3% of reading value, but at least ± 0.3 l / min |

|---|---|

| Connection type | Internal thread, G ¼ " |

| Contact rating max | 50 VA |

| Electrical connection | 1.5 m fused cable |

| Flow max | 10 l/min |

| Flow range max | 9 l/min |

| Flow range min | 0,4 l/min |

| Function | Flask, reed contact |

| IP class | IP65 |

| Material flask | Stainless steel 303 |

| Material of body | Nickel-plated brass |

| Material of connection | Bronze |

|---|---|

| Material of seals | NBR |

| Material spring | Stainless steel 301 |

| Pressure drop | Approx. 0.4 bar at maximum flow |

| Pressure range max | 200 bar |

| Temperature of media to | 110 °C |

| Type of flow component | Flow Switches |

| Weight | 0,6 kg |

| Viscosity max | 1 cSt |

| Voltage ac max | 230 V |

Product description

The Honsberg FF series flow switch is a simple unit which indicates when a specific flow rate has been acheieved. The basic operation of the switch is when the volume flow raises a piston (fitted with a magnet) out from a valve seat which is against a spring force and when the specificed flow rate is achieved the piston actuates an hermetically separated reed switch. The FF is designed for horizontal inwards flow; switching head not recommended underneath; other installation positions are possible; the installation position affects the switching point and range.

*The switch point must always be specified/factory-set item

- Adjusted switching value

- Highly reproducible

- Insensitive to dirt

- Adjustment for oil or gas

- Special values

Ordering information

*The switch point must always be specified/factory-set item

- Specify direction of flow, medium, and switching point.

- For oils, state viscosity, temperature and designation (e.g. ISO VG 68) (enquire about range).

- For gases, state pressure (relative or absolute), temperature and medium (e.g. air) (enquire about range).

Installation

- Include straight calming section of 5 x DN in inlet and outlet.

- If the media are dirty, install a filter (use magnetic filter for ferritic components).

- It must be ensured that the values given for voltage, current, and power are not exceeded.

- When switched on, a load must be connected in series. The electrical details apply to ohmic loads. Capacitive, inductive and lamp loads must be operated using a protective circuit.

- Standard: horizontal inwards flow; switching head not recommended underneath; other installation positions are possible; the installation position affects the switching point and range.

Related

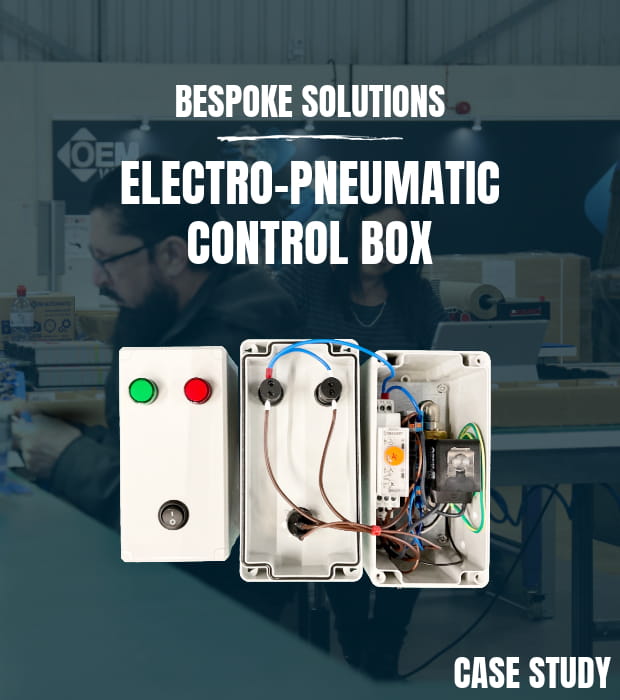

Case Study - Electro Pneumatic Control Box

At OEM Automatic, we can supply a series of components for your one project. All under one roof. This case study discusses how we supplied several components for our customer's new electro-pneumatic control box.

New Hydrogen Approved Pressure Switches

OEM is pleased to announce a range of hydrogen-approved mechanical pressure switches, by Suco! Today, hydrogen plays a key role in climate-neutral energy generation and storage.

Feel the force with Wika force measurement

OEM Automatic proudly welcomes the addition of WIKA to its lineup. Wika Force brings a new dimension to the realm of force measurement. The integration of WIKA into the OEM Automatic pressure and flow range represents a significant advancement in force measurement technology!

Georg Fischer New Process Automation Supplier

Georg Fischer is a globally renowned provider of process automation systems and solutions for various industries. Join us as we delve into the advantages and opportunities that this new addition brings to you.

ESI's hydrogen compatible pressure sensor range

Using hydrogen as a source of energy is an emerging market. ESI have a selected range of pressure sensors that are hydrogen-compatible.

Process and packaging automation components at OEM

Automated machinery in the process and packaging industries is constantly developing. Find out how we can help to automate process and packaging machinery at OEM.