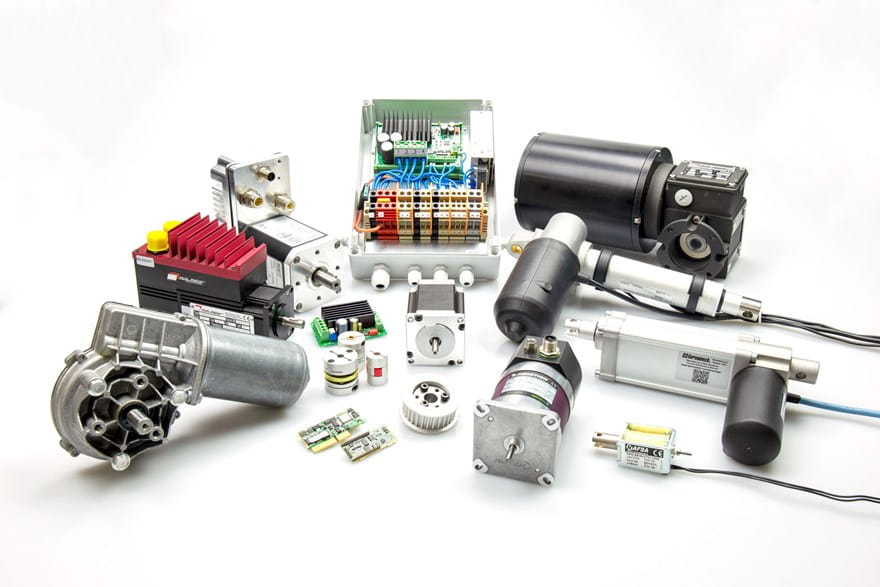

Motors

An extensive product range backed up with many years’ worth of expert knowledge ensures that we can find the perfect solution for your needs.

We take pride in offering full technical advice on all aspects of product selection. Our team is always on hand to answer your questions and help you find the right product for your application.

Whether you need standard or customised products for OEM applications, we have you covered

AC Motors

DC Motors

Brushless Motors

Servo Motors

Ironless DC Motors

Stepper Motors

Format Changeover

IP67 Clean Motors

IP69K Stainless Steel Motors

AGV Drive Wheels

Motion control and intelligent drives

Motor Drives

Modular Gearboxes

Linear & Mechanical Products

Related

How to select the right motor

Determining what motor to use is quite a daunting task. Our Motors experts have developed a guide to show the steps to determine a suitable motor.

Synchronous Motors

Do you have a light duty motor requirement requiring a very stable output rpm ? If so, Crouzet synchronous motors are could well provide you ideal solution…

Recap of IATECH

Did you get a chance to visit IATECH at The Leicester Marriott Hotel? We had over 33 exhibitors and 8 fantastic Tech Talks throughout the day, Read all about the day, here.

OEM introduces IATECH - The Industrial Automation Technology Expo

We are thrilled to announce the launch of IATECH, THe Industrial Automation Technology expo at Leicester Marriott Hotel on 23rd October. The ultimate platform for showcasing our extensive product range and broad business areas, featuring over 50 leading suppliers under one roof!

Automation Components for Specialist Vehicles

The specialist vehicle industry can include automotive and EV, heavy vehicles such as agriculture and rail, and marine. This email takes you through some of the various products we offer for specialist vehicle applications.

Wheel motor drives for AGVs

AGV drive wheel motors cover a wide range of options – from a miniature unit on a small 20kg robot, tasked to move on a perfectly level and smooth indoor surface, up to passenger vehicle-sized robots working outside over fields and varying terrain.