DEFINOX

Definox - NEOS

Pneumatic

Definox NEOS Valve.

Meets the strongest requirements for process technology and is the ideal solution for food, brewery, cosmetics, and pharmaceutical processes. This seat valve design offers a wide range of options and variants.

NEOS double sealed valve, with leak detection and without elastomer seal, combines different technologies into a unique result to meet market demands in terms of cleaning, durability and sanitary applications.

The NEOS valve benefits from patented technology and meets the recommendations of EHEDG in its design. The valve is especially suitable for CIP "Cleaning In Place" since the valve does not use elastomeric gaskets in contact with the process fluid.

It is an economically attractive alternative to double seat valves as it provides a sufficient level of protection for product lines prior to pasteurization and supply networks (CIP - water flush), allowing frequent cleaning and use of aggressive products.

Technical Advantages:

- From DN 25 to 104

- PTFE deformable sealing diaphragm- provides a physical barrier to the outside.

- Leak indicator NO and cleaning microvalve are controlled separetly unsing ACS control unit

- Spherical body with thick walls - ensures excellent resistance to expansion.

- Different body configurations possible - + T L

- single peice plug without threads or welds.

- Pneumatic actuator - removable and easily transformable NO-NC

- Supports overpressures under the plg with release to the leak chamber

- Leak indicator - instantaneous visualisation if any leaks

- Complete interchangability of subcomponents

- NEOS double sealed valve

- Leak Detection

- Economically attractive

- PTFE membrane

- PFA elastomeric structure

Selected variant

Technical data

| Certificate | 3.1 EN10204 |

|---|---|

| Connection type | Weld ends |

| Description | EHEDG Design |

| Design norm | SMS |

| Housing | L1-Body |

| Housing | PFA |

| Inner diameter | 22,6 mm |

| Material controls | Stainless steel AISI 304 |

| Material membrane | PTFE |

| Material quality | 1.4404 |

| Material seat seal | PFA |

|---|---|

| Operating pressure max | 8 bar |

| Outer diameter | 25 mm |

| Pilot pressure max | 7 bar |

| Pilot pressure min | 5,5 bar |

| Surface finish | RA<0,8/1,2µm |

| Temperature range | -5°C/+140°C |

| Weight | 4,5 kg |

Product description

Definox NEOS Valve.

Meets the strongest requirements for process technology and is the ideal solution for food, brewery, cosmetics, and pharmaceutical processes. This seat valve design offers a wide range of options and variants.

NEOS double sealed valve, with leak detection and without elastomer seal, combines different technologies into a unique result to meet market demands in terms of cleaning, durability and sanitary applications.

The NEOS valve benefits from patented technology and meets the recommendations of EHEDG in its design. The valve is especially suitable for CIP "Cleaning In Place" since the valve does not use elastomeric gaskets in contact with the process fluid.

It is an economically attractive alternative to double seat valves as it provides a sufficient level of protection for product lines prior to pasteurization and supply networks (CIP - water flush), allowing frequent cleaning and use of aggressive products.

Technical Advantages:

- From DN 25 to 104

- PTFE deformable sealing diaphragm- provides a physical barrier to the outside.

- Leak indicator NO and cleaning microvalve are controlled separetly unsing ACS control unit

- Spherical body with thick walls - ensures excellent resistance to expansion.

- Different body configurations possible - + T L

- single peice plug without threads or welds.

- Pneumatic actuator - removable and easily transformable NO-NC

- Supports overpressures under the plg with release to the leak chamber

- Leak indicator - instantaneous visualisation if any leaks

- Complete interchangability of subcomponents

Related

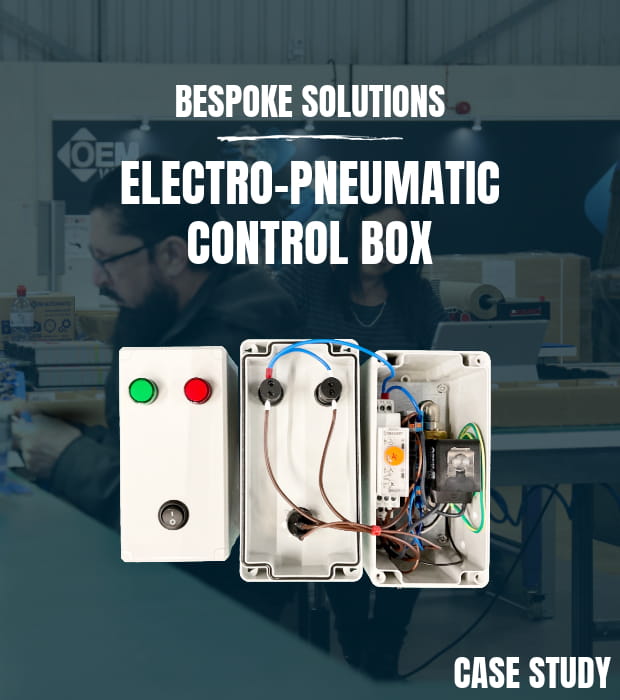

Case Study - Electro Pneumatic Control Box

At OEM Automatic, we can supply a series of components for your one project. All under one roof. This case study discusses how we supplied several components for our customer's new electro-pneumatic control box.

New Hydrogen Approved Pressure Switches

OEM is pleased to announce a range of hydrogen-approved mechanical pressure switches, by Suco! Today, hydrogen plays a key role in climate-neutral energy generation and storage.

Feel the force with Wika force measurement

OEM Automatic proudly welcomes the addition of WIKA to its lineup. Wika Force brings a new dimension to the realm of force measurement. The integration of WIKA into the OEM Automatic pressure and flow range represents a significant advancement in force measurement technology!

Georg Fischer New Process Automation Supplier

Georg Fischer is a globally renowned provider of process automation systems and solutions for various industries. Join us as we delve into the advantages and opportunities that this new addition brings to you.

ESI's hydrogen compatible pressure sensor range

Using hydrogen as a source of energy is an emerging market. ESI have a selected range of pressure sensors that are hydrogen-compatible.

Process and packaging automation components at OEM

Automated machinery in the process and packaging industries is constantly developing. Find out how we can help to automate process and packaging machinery at OEM.