CAL CONTROLS

CAL - 3300, 9300, 9400

Series 3300, 9300, 9400

Temperature controllers, also used as indicating instruments. These three models offer identical functionality, the format separates 3300 from the others and 9400 displays both the actual and set point values. In general they offer the same control and output performance as well as two outputs. The controllers are ordered with the following output combinations: 5 V/relay, relay/relay or 5 V/5 V. See the order numbers for stocked alternatives. We recommend to control most loads via the 5 V output (SSD) to maximise the controller life length. This output can control solid state relays directly or optocouplers, which in turn control, e.g. contactors or solenoid valves. If the controller is to be used as a panel instrument select 3300 or 3311 on account of the format. Here type 3311 (two relay outputs) is usually more appropriate, as the relay output is easier to match to different alarm or indication functions, e.g. input to control system.

Series 9500P Process controller/program controller

This is an advanced process controller and program controller, yet is still easy to program. The controller can be used both as a temperature controller or process controller for other units, e.g. pressure, flow, level or other signal from a linear sensor. 9500P is equipped with special functions to manage linear input signals, with regard to scaling and display range (display up to 9999). In the standard version it supports two- or three-wire PT100, thermocouples and linear input signals via external resistors (see connection). In other versions it is purchased for a specific input signal such as 4-20 mA or 0-10 V. 9500P has three outputs, see order numbers for stocked alternatives. - output 1 and 2 relay, SSD (6 V) or analogue output can be chosen - output 3 always has a relay output.

As profile controller

This controller can be used in application that demand several temperature steps, i.e. the temperature is automatically ramped up or down to one or more set point values at which the temperature is to be maintained during a set time. The program profile is either created using the buttons or even easier and clearer in the CALgrafix software (the program profile is drawn using “drag and drop” with the mouse). Up to 31 program profiles can be saved, one profile can comprise 126 segments (step). The number of stored programs and the size per program is restricted by the controller’s total memory capacity. However, this restriction does not apply if the controllers are connected to the CALgrafix software, as a large number of programs can be saved on the computer.

Example of a program profile |

|

The example shows a program with seven segments, for ramping to different temperatures. The programs can be copied and modified, |

Other functions

- 10 year memory in the event of a power outage

- Input signal PT100, thermocouple or linear signals, 4-20 mA, 0-10 V

- Rescaling to another unit, e.g. pressure, flow

- Three year warranty against manufacturing defects

- Waterproof front, IP66

- Alarm functions (low-high alarm, etc)

- Lockable settings at different levels

- Heating/cooling control

- Ramp function/soak time

- Can be calibrated e.g. for cable resistance (PT100)

About control

Self-tuning that optimises all PID parameters to the process/machine should be performed to give the best control result. The controllers have a very high control performance to produce a good result even in difficult control instances. Control can occur with e.g. contactors via the relay output or with the 5 V output that usually controls a solid state relay. 9500P is also available with an analogue control output as an option. Output 2 can be used as an alarm output or for cooling control in e.g. plastic machines. 9500P has a third relay output for alarms.

We recommend controlling heating loads with solid state relays that are controlled directly from the controller’s 5 V-output; this allows the cycle time to be lowered to “pulse” the supply at heat over a sufficient period and thereby maintain an even temperature which quickly responds to temperature changes. In addition, this gives low power consumption during energy demanding processes such as plastic and rubber production. Solid state relays have no moving parts that can wear, which gives a longer life length than contactors and do not generate any interference when opening and closing.

Analogue control

For analogue control the CAL 9500P should be selected, which is available in 4-20 mA, 0-10 V or 0-5 V output versions. This can be partly used as a control output, but also as a 'retransmit' measurement signal to other systems, to e.g. reflect the input signal’s measurement value.

Ramp function

All digital controllers have a ramp function where you state the required temperature increase in °C/h for slow heating of e.g. plastic tools, ceramic ovens, etc. There is also a time function that switch off the output after a set control time when the set point value has been reached.

About communication

The controllers can be used as independent field instruments where setting of set point values and all other configuration is performed using the three buttons on the front. The controllers can also be connected to a personal computer and works together with CAL’s software (See Software); up to 128 CAL instruments can be connected simultaneously via ModBus ® protocol to a RS485 interface, alternatively RS232 for the connection of one controller to a PC. The controllers can also be connected to another master system via OPC.

The most common application is four to ten instruments where the software control/monitors one machine or one product. The total investment cost falls with an increased number of connected instruments, but controllers with communication can be cost effective already with one or a pair of instruments to monitor/log an important process. Likewise during mass production of a product where the instrument has the same or recurring configuration. The settings are saved in software and are transferred to the instrument without the risk of incorrect settings.

This system permits each instrument to continue to control its process even in instances where the PC and/or communication has been knocked out or taken out of operation.

The display picture can show instruments, where they normally show the current actual value, i.e. reflects the value on the “true” field instrument. In the event of errors in the process, error messages are shown on the instrument and on the corresponding “screen instrument” in the control room.

Selection of products for communication

If only one instrument is to be connected to the software, instruments with a RS232 card can be chosen. The cable length between the instrument and PC must then be 15 metres at most to guarantee secure signal transfer. As the instrument select e.g. 330000208 and cable 4303000C2. An adapter is not needed as the computer’s communication port normally gives this signal.

If more than one instrument is to be connected and/or the cable length exceeds 15 metres, select instruments with a RS485 card, for example 330000408 and cable type 4303000C4 for industrial use. Here an interface converter type 3C2400000 is usually required as a PC normally does not have this interface in-built.

We supply all component products for a complete system.

The aforementioned components are recommended to give the best solution, i.e. adapters and cables that our supplier has produced to quickly and safely build a fully functional installation. We cannot be held responsible for any malfunction where other components have been used.

- Self-tuning of all PID parameters

- Clear display, intensive digits

- Well-arranged, easy-to-understand menu system

- Communication to PC for configuration / logging

Selected variant

Technical data

| Communication | N/A |

|---|---|

| Control type | PID, ON/OFF, Alarm, Ramp, Soak, dAC |

| Dimensions | 24x48 |

| Display colour | Green |

| Input type | Thermocouple, PT100 (2 wire), 0-50mV |

| IP class front | IP66 |

| Output | Logic (SSR), Relay |

| Supply voltage | 100-240 V AC |

Product description

Series 3300, 9300, 9400

Temperature controllers, also used as indicating instruments. These three models offer identical functionality, the format separates 3300 from the others and 9400 displays both the actual and set point values. In general they offer the same control and output performance as well as two outputs. The controllers are ordered with the following output combinations: 5 V/relay, relay/relay or 5 V/5 V. See the order numbers for stocked alternatives. We recommend to control most loads via the 5 V output (SSD) to maximise the controller life length. This output can control solid state relays directly or optocouplers, which in turn control, e.g. contactors or solenoid valves. If the controller is to be used as a panel instrument select 3300 or 3311 on account of the format. Here type 3311 (two relay outputs) is usually more appropriate, as the relay output is easier to match to different alarm or indication functions, e.g. input to control system.

Series 9500P Process controller/program controller

This is an advanced process controller and program controller, yet is still easy to program. The controller can be used both as a temperature controller or process controller for other units, e.g. pressure, flow, level or other signal from a linear sensor. 9500P is equipped with special functions to manage linear input signals, with regard to scaling and display range (display up to 9999). In the standard version it supports two- or three-wire PT100, thermocouples and linear input signals via external resistors (see connection). In other versions it is purchased for a specific input signal such as 4-20 mA or 0-10 V. 9500P has three outputs, see order numbers for stocked alternatives. - output 1 and 2 relay, SSD (6 V) or analogue output can be chosen - output 3 always has a relay output.

As profile controller

This controller can be used in application that demand several temperature steps, i.e. the temperature is automatically ramped up or down to one or more set point values at which the temperature is to be maintained during a set time. The program profile is either created using the buttons or even easier and clearer in the CALgrafix software (the program profile is drawn using “drag and drop” with the mouse). Up to 31 program profiles can be saved, one profile can comprise 126 segments (step). The number of stored programs and the size per program is restricted by the controller’s total memory capacity. However, this restriction does not apply if the controllers are connected to the CALgrafix software, as a large number of programs can be saved on the computer.

Example of a program profile |

|

The example shows a program with seven segments, for ramping to different temperatures. The programs can be copied and modified, |

Other functions

- 10 year memory in the event of a power outage

- Input signal PT100, thermocouple or linear signals, 4-20 mA, 0-10 V

- Rescaling to another unit, e.g. pressure, flow

- Three year warranty against manufacturing defects

- Waterproof front, IP66

- Alarm functions (low-high alarm, etc)

- Lockable settings at different levels

- Heating/cooling control

- Ramp function/soak time

- Can be calibrated e.g. for cable resistance (PT100)

About control

Self-tuning that optimises all PID parameters to the process/machine should be performed to give the best control result. The controllers have a very high control performance to produce a good result even in difficult control instances. Control can occur with e.g. contactors via the relay output or with the 5 V output that usually controls a solid state relay. 9500P is also available with an analogue control output as an option. Output 2 can be used as an alarm output or for cooling control in e.g. plastic machines. 9500P has a third relay output for alarms.

We recommend controlling heating loads with solid state relays that are controlled directly from the controller’s 5 V-output; this allows the cycle time to be lowered to “pulse” the supply at heat over a sufficient period and thereby maintain an even temperature which quickly responds to temperature changes. In addition, this gives low power consumption during energy demanding processes such as plastic and rubber production. Solid state relays have no moving parts that can wear, which gives a longer life length than contactors and do not generate any interference when opening and closing.

Analogue control

For analogue control the CAL 9500P should be selected, which is available in 4-20 mA, 0-10 V or 0-5 V output versions. This can be partly used as a control output, but also as a 'retransmit' measurement signal to other systems, to e.g. reflect the input signal’s measurement value.

Ramp function

All digital controllers have a ramp function where you state the required temperature increase in °C/h for slow heating of e.g. plastic tools, ceramic ovens, etc. There is also a time function that switch off the output after a set control time when the set point value has been reached.

About communication

The controllers can be used as independent field instruments where setting of set point values and all other configuration is performed using the three buttons on the front. The controllers can also be connected to a personal computer and works together with CAL’s software (See Software); up to 128 CAL instruments can be connected simultaneously via ModBus ® protocol to a RS485 interface, alternatively RS232 for the connection of one controller to a PC. The controllers can also be connected to another master system via OPC.

The most common application is four to ten instruments where the software control/monitors one machine or one product. The total investment cost falls with an increased number of connected instruments, but controllers with communication can be cost effective already with one or a pair of instruments to monitor/log an important process. Likewise during mass production of a product where the instrument has the same or recurring configuration. The settings are saved in software and are transferred to the instrument without the risk of incorrect settings.

This system permits each instrument to continue to control its process even in instances where the PC and/or communication has been knocked out or taken out of operation.

The display picture can show instruments, where they normally show the current actual value, i.e. reflects the value on the “true” field instrument. In the event of errors in the process, error messages are shown on the instrument and on the corresponding “screen instrument” in the control room.

Selection of products for communication

If only one instrument is to be connected to the software, instruments with a RS232 card can be chosen. The cable length between the instrument and PC must then be 15 metres at most to guarantee secure signal transfer. As the instrument select e.g. 330000208 and cable 4303000C2. An adapter is not needed as the computer’s communication port normally gives this signal.

If more than one instrument is to be connected and/or the cable length exceeds 15 metres, select instruments with a RS485 card, for example 330000408 and cable type 4303000C4 for industrial use. Here an interface converter type 3C2400000 is usually required as a PC normally does not have this interface in-built.

We supply all component products for a complete system.

The aforementioned components are recommended to give the best solution, i.e. adapters and cables that our supplier has produced to quickly and safely build a fully functional installation. We cannot be held responsible for any malfunction where other components have been used.

Related

Efficient crimping, punching and stripping

Renowned for high-quality cable cutting and crimping tools, Klauke serves electrical contractors, cable jointers, and linemen across a spectrum of sectors

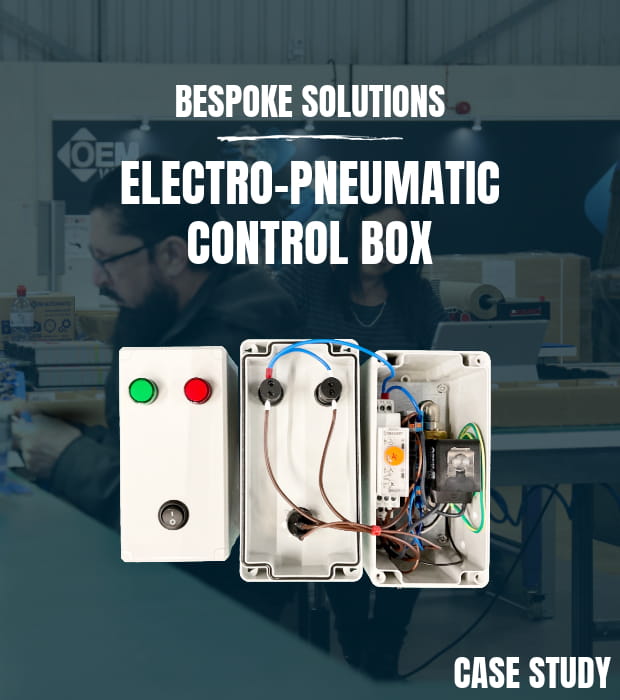

Case Study - Electro Pneumatic Control Box

At OEM Automatic, we can supply a series of components for your one project. All under one roof. This case study discusses how we supplied several components for our customer's new electro-pneumatic control box.

Cable Protection For Emobility

To promote constant and reliable performance, as well as a longer life of parts in the vehicle, it is important to consider the right cable protector.

Switch disconnectors without compromise

We have now added switch disconnectors to our range! Switch disconnectors contribute to the overall functionality and safety of electrical systems.

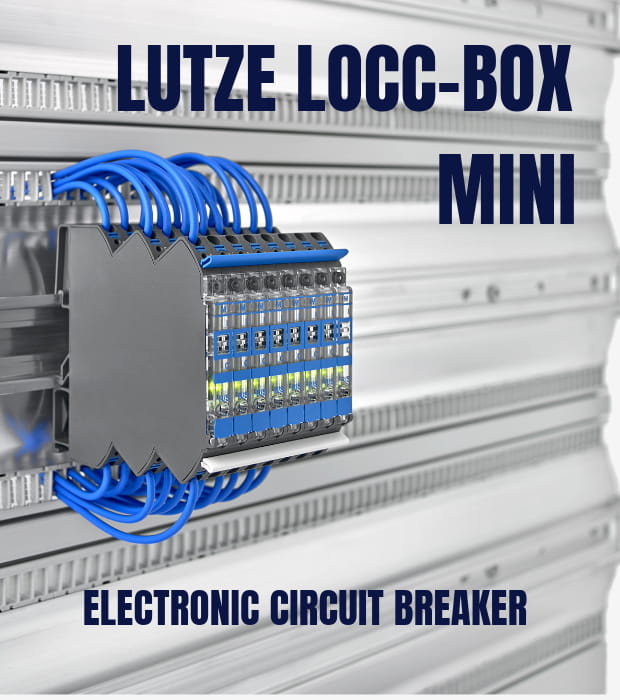

Electronic Circuit Breaker - LoccBox

LOCC-Box from Lutze is an intelligent current monitoring device that provides reliable protection of DC circuits in a slimline 8.1mm housing.

The Push In Technology You Need at OEM Automatic

OEM Automatic has integrated push-in technology into it's product offering for many years now. In this blog post, we'll explore the various benefits of push-in technology and some of the products we offer that make use of this innovation, such as push-in terminals, push-in sockets, and even push-in heaters.